Not surprisingly, scientists have struggled to find an artificial substitute for natural knee cartilage – it’s a surprising biological substance that combines the properties of a soft cushion and a tough barrier to prevent our busy leg joints from being damaged.

But it looks like we’ve made a long-awaited breakthrough: The researchers believe they may have finally developed a material that matches the cartilage found in our bodies, and that could be used as a replacement after injury or in old age.

“We set out to make the first hydrogel that has the mechanical properties of cartilage,” says chemist Ben Wiley of Duke University.

A significant number of people could benefit from something like this, as more than 790,000 knee replacements are performed each year in the US Currently, those replacements, which involve fairly invasive surgery, may last only a couple of decades before. that they need to be replaced again.

Imagine if you could replace just the worn or damaged cartilage, instead of having to tear the entire knee joint.

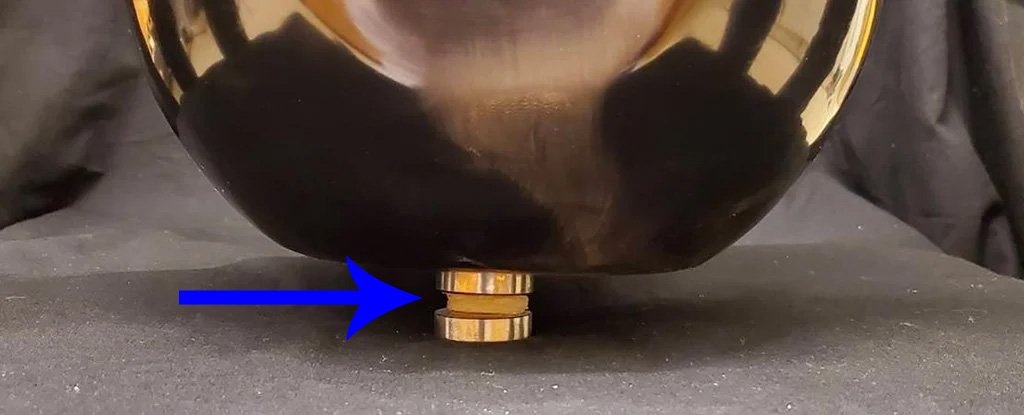

As with other hydrogels, the main ingredients in this new material are water-absorbing polymers: in this case, a polymer made of spaghetti-like yarns, woven together with another polymer that is less flexible and more basket-like. A third polymer, made from cellulose fibers, acts as a mesh that holds everything together.

When the material is stretched, it is the third polymer that keeps the gel intact. When squeezed, polymers one and two, with negative charges extending along their length, repel each other and adhere to water, so the original shape can be restored.

The hydrogel performed best in these two crucial categories (stretch and crush) and showed better performance than other existing hydrogels. In a test of 100,000 repeated pulls, the artificial cartilage was maintained as well as the porous titanium material used in bone implants.

“Only this combination of the three components is flexible and rigid and therefore strong,” says materials scientist Feichen Yang, also from Duke University.

In tests in which the hydrogel was rubbed against natural cartilage a million times, no less, it was shown to be as resistant to wear and tear as in reality, and more durable than the artificial cartilage used in operations today. big toe (notable because that gel has regulatory approval in the US).

However, getting this new hydrogel approved for use in humans could take up to three years, the researchers say, so there is still a way to go before patients can take advantage of the innovation.

Until now, the non-toxicity of the hydrogel has only been tested against laboratory-grown cells. The next step is to see if it can be safely transplanted into sheep, and only after that can tests be done on real people.

However, over time, the new material holds great promise as an option for those experiencing knee pain: They might someday restore joint function, without long recovery times or a short lifespan for replacement cartilage. It should help until we learn to regenerate our own cartilage, at least.

The research has been published in Advanced functional materials.

.