[ad_1]

With Samsung Electronics signing a contract for consignment production of semiconductors with Intel, we expect to make large-scale investments to become the number one foundry market.

According to the semiconductor industry on the 22nd, Samsung Electronics recently signed a contract for production on consignment with Intel for PC motherboard chipsets (PCH) and 5G base station chipsets, and is considering expanding investments in production facilities of domestic and foreign foundry.

A semiconductor industry official said: “This production on consignment contract with Intel is not for expensive chipsets such as CPUs and GPUs, but considering the situation where the global foundry market suffers from insufficient capacity, the scope of the The cooperation will be extended to various items in the future. You can see that it has laid the foundation for expansion, “he said.” Samsung Electronics also currently lacks capacity, and if an additional shipping contract is concluded, it is unlikely to invest in domestic and foreign products. production facilities. “

In fact, in a conference call for the fourth quarter of 2020 on the 21st (US local time), Intel said: “Intel has solved the problem of the 7 nanometer process by itself, and most of the 7-nanometer processors to be launched in 2023 will be manufactured in-house. “However, the volume of outsourcing (consignment production) will increase compared to the past. Details will be communicated after the new CEO takes office (February 15), “he said, indicating the possibility of an additional production contract.

In the market, Samsung Electronics is said to invest more than 12 trillion won this year in memoryless semiconductor field alone (foundry, LSI system) considering this situation. TSMC, the number one foundry market, revealed its plans to invest in facilities worth half of 30 trillion won, the most this year.

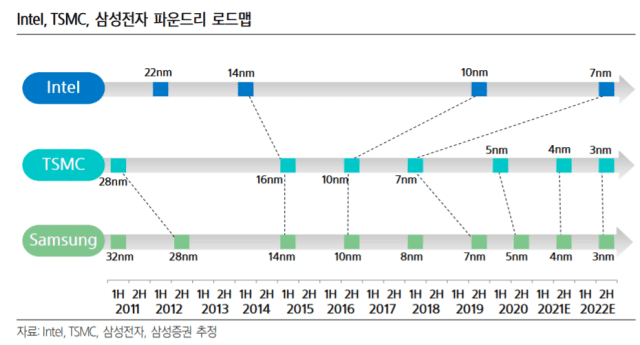

A securities industry official said: “Currently, TSMC and Samsung Electronics are the only foundry companies in the world that can consign 7nm and 5nm chipsets. And the share of 7nm and 5nm in total foundry production will increase more quickly. ” that Samsung Electronics has no choice but to invest in domestic and foreign production facilities, including Austin, as it is necessary to prepare in advance for 4 and 3 nanometer production in order to close the gap with TSMC. “

In the domestic materials, spare parts and equipment industries, there are also observations that Samsung Electronics will focus investment in the US (Austin) rather than Korea (Pyeongtaek). The reason is that the Austin plant is close to the headquarters of major semiconductor companies like Intel, AMD, Nvidia, Qualcomm, etc., and the supply chain risk generated by Corona 19 is low, so it is a lot more advantageous to win new ones. orders.

Related Posts

Intel, self-manufacturing 7nm chips and production on consignment at the same time … will Samsung drop it?

Intel “7nm processors in 2023, manufactured in-house”

“Intel signed a contract for the production of consignment chips with Samsung Electronics”

“Increased the proportion of Exynos installed in the Galaxy S21 to 60%”

An equipment industry official said: “A national company with a US subsidiary has begun preparations to scale up investment in facilities near the Samsung Electronics plant in Austin, and some equipment companies have are moving rapidly, including the process of transporting semiconductor equipment to the US “The industry expectation for the expansion of investment in memoryless semiconductors from Samsung Electronics is high,” he said.

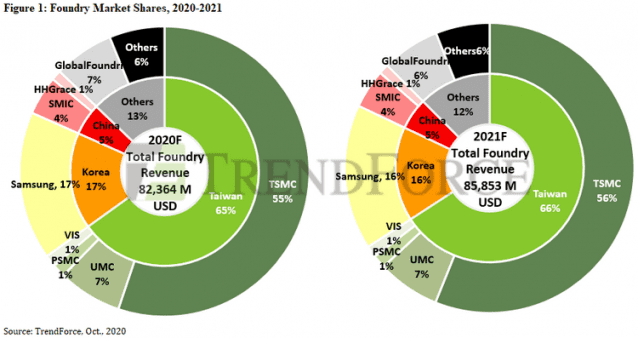

Meanwhile, according to Trend Force, a market research firm, Samsung Electronics ranked second in the global foundry market (based on sales) last year with a 17% share. TSMC, the number one in the market, recorded a 54% market share and the gap between the two companies reached 37%.