[ad_1]

Check-in 2021.01.01 20:00

One hundredth of a hair, one-tenth of a thousandth of a conventional glass lens

Only infrared yet … “Cameras and sensors commercialization in 3 years”

‘Katuktu’ Smartphone Expected To Solve With Follow-up Investigation On Visible Light Lenses

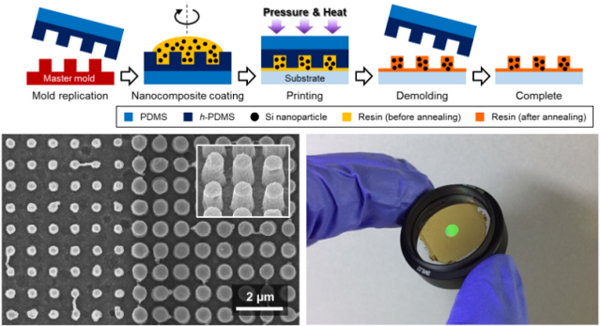

The Ministry of Science and Technology, Information and Communication announced that the joint research team of Joon-Seok Noh, Professor of Mechanical Engineering and Chemical Engineering at POSTECH, and Seung-Hoon Han, Master in Imaging Device Laboratory at the Institute of Samsung Electronics Advanced Technology, developed the world’s first ultra-thin infrared ‘goal lens’ and mass production technology using ‘goal material’. Sun said.

The results of the research were published in the journal ‘ACS Nano’ published by the American Chemical Society (ACS) on this day. The joint research team plans to commercialize this technology as an infrared camera lens three years later and then apply it to smartphone cameras.

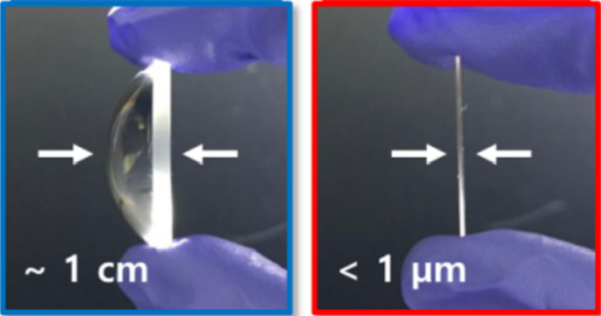

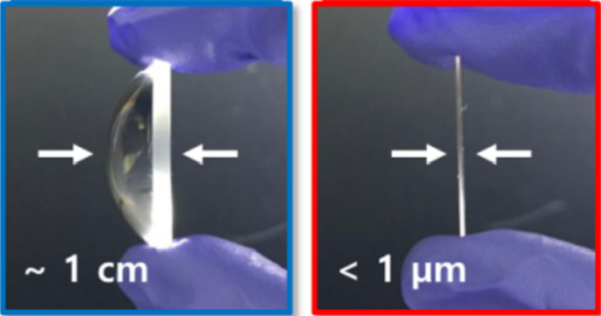

To collect light and obtain a clear image, you need a convex lens that deflects the direction of the light and collects it at one point. Existing convex glass lenses must be at least 1 cm thick to capture light effectively. This is the reason why the lens weight of high-performance DSLR cameras exceeds 4 kg, and smartphone cameras also have technical limitations in thickness compression.

A meta lens is a flat lens in which 50 nanometers (nm · 1 billionth of a meter) of nanoparticles are regularly arranged on the surface. Although it’s not actually convex, the nanoparticles refract light and collect it at one point like a convex lens.

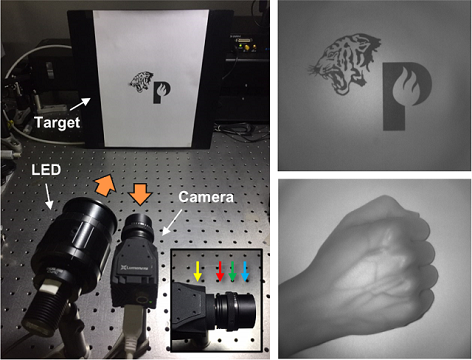

As a result of attaching a test lens with a diameter of 4 mm to the real infrared camera, the research team performed the same function as the existing infrared camera, such as photographing the distribution of blood vessels in human skin.

Professor Roh said: “Time to market is expected to be 3 to 5 years later.” .

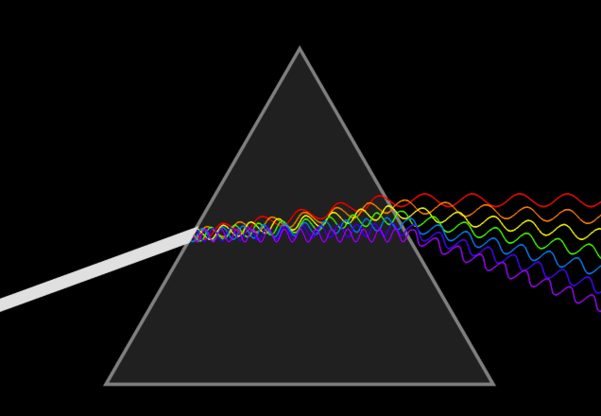

Metalenses can only be used to collect infrared light, not visible. Visible light lenses have already been developed, but the red, orange, yellow, green, blue, indigo, and violet lights that make up visible light have different refractive indices (the degree of curvature as they pass through the lens), for what they separate from each other as they pass through the lens. It remains. The research team plans to solve this problem and apply the technology to cameras and visible light sensors in general.