[ad_1]

Korea’s premium era: let’s run Korea again

(1) The crisis as an opportunity … Start with companies

“Why are Korean stocks cheaper than global companies in similar industries?”

The word used for a long time in response to this question is “Korean Discount”. There are many reasons why Korean companies have been undervalued. It has been established that the security risks of geopolitical location, backward practices far from world standards and militant labor movements have combined to have a negative impact on the image of Korea.

○ There is no ‘Korean discount’

The biggest damage to Korea’s discount was export SMEs. This is because the “national” label does not help companies like this. The story of German and Italian companies using national brands and building images of “technical skills” and “luxury goods” was literally about a different country.

The situation has changed four or five years ago. With the Korean Wave, the number of global consumers seeing Korea positively increase. A new variable called coronavirus infection (corona19) has been added. With Crown 19 of Korea, Korea has a new positive image of “the country with the most advanced social system”.

The word ‘Korea Premium’ is already appearing among companies. An example is Wonbong, a medium-sized consumer electronics company that exports 70% of its products to Russia, the Middle East, and Southeast Asia. The company has been incorporating Taegeukgi patterns in some export products, such as water purifiers, hot and cold water purifiers, and air purifiers, at the request of Middle Eastern buyers for five years. The “made in Korea” origin mark was also attached to the front, not the corner of the product.

Wonbong’s “Korea Marketing” has become more active since Corona19. In Korea, Egypt, Vietnam and Malaysia, the word ‘Korea’ is also included in Korean. Importers are also welcoming ‘Korea Marketing’. A company official said, “There are some places where local customers have separately made and attached Taegeukgi patterns after importing products.”

Wonbong air purifier sales peaked in the first quarter of this year. Sales volume increased by 70% during the same period last year. Founder Kim Young-don said he felt a sense of outrage. He said, “When I entered the textile trade business in 1987, I simply put ‘Made in Korea’ as a decal to hide what was made in Korea, so that it could be removed in the field.

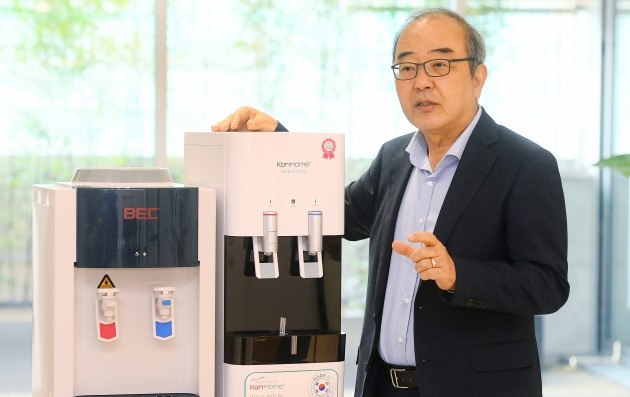

President Wonbong Kim Young-don presents an export product with a sticker containing the phrase “made in Korea” and Taegeukgi on the bottom of the water purifier. Reporter Kang Eun-gu [email protected]

○ Rediscovering a “chimney company”

In the field directly related to Corona 19, ‘Korea Premium’ is bigger. Fabric Time and the Dytek Research Institute sold 500,000 yards (457.2㎞) of fabric to nonwoven fabrics used in protective clothing last month to New York State hospital clothing manufacturers. It was a ‘face-to-face export’, where the contract was made at a direct rate without finding a business partner.

Thanks to the reputation of “preventative power”, an “SOS” request was first received locally. The first contact was Fabric Time, a fabric export platform company. The company was asked to find a substitute for a non-woven fabric and went to the Dytek Institute for help. The Dytek Institute, which knew the testing standards of the United States, immediately developed an alternative material and shipped products to the United States through time on the web. The time needed to develop alternative materials, hire and deliver was only one week.

Another point has changed from Corona 19. The re-evaluation work is being carried out in the manufacturing industry, which was classified as a specification industry. Samsung Electronics, Hyundai Motors and SK Hynix showed that manufacturing companies are resilient to the crisis in the first quarter with “surprising results.” It is said to have shown that not only the technological level but also the crisis management capacity is the best in the world.

The assessment of small and medium manufacturers also changed. Strategy and Finance Minister Kim Yong-beom said on his Facebook page on 11 of last month: “The economy is holding up so much because of the high proportion of manufacturers in the national economy and its ability to compete.” He said, “I want to tell hundreds of thousands of manufacturers and workers that they are ‘our hidden heroes.'”

There are remaining tasks. Experts say Korean manufacturers need more investment in technology, quality and design to fully enjoy “Korea Premium”. Professor Lee Na-kyung, professor of economics at Seoul Women’s University, said: “To change the ‘favorite’ of Korean companies into ‘pansim’, we need to increase our global competitiveness.”

Reporter Song Hyeong-seok / Nokyung Mok [email protected]