[ad_1]

The US White House is holding an emergency response meeting with leading semiconductor and finished car companies such as Samsung Electronics and General Motors for quality of semiconductor supply. When it comes to economics, the Biden administration, which advocates “ self-priority, ” similar to that of the previous Trump administration, is taking the phenomenon of semiconductor shortages as an opportunity to expand production in the United States. . In fact, it is known that the semiconductor supply chain will be the focus of discussion at this meeting.

Chaired by US National Security Advisers, Semiconductor Emergency Meeting

According to US media on the 2nd, senior White House security and economic officials will discuss the global semiconductor supply shortage with officials from semiconductor companies and automakers on the 12th. Major US manufacturers will attend. like General Motors (GM) and Global Foundry. Also invited were Samsung Electronics, which is number one in the memory semiconductor market and produces memoryless semiconductors in the U.S. In the U.S. government, National Security Advisor Jake Sullivan and Chief Executive Officer will attend. the National Economic Commission, Brian Deeds. A reluctant US government official said in an interview with US media that “we are also working with Congress and its allies on the semiconductor shortage.” As announced by the US government, the background to the emergency meeting is related to the global shortage of semiconductors. In particular, as the disruption in the supply of non-memory semiconductors for automobiles, which has a major impact on the broader economy, has worsened over the past three to four months, it has spread to related industries and companies such as auto parts manufacturers. ‘Semiconductor shortage → car production disruption → is realizing the slowdown in employment and economic recovery in the dark scenario.

Black Swan, semiconductor shortage phenomenon

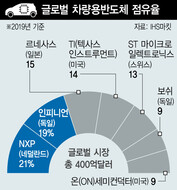

Semiconductor shortage is the result of overlapping coincidence with coincidence. First of all, companies that produced semiconductors for automobiles increased the proportion of semiconductor production for PCs and mobiles by witnessing the phenomenon that automobile production decreased significantly due to the impact of Corona 19 last year. This means that with the revitalization of the remote economy, the supply of semiconductors for vehicles has been reduced by switching to electronics companies, where the demand has increased considerably. In addition, unexpected natural disasters occurred in various parts of the world where the semiconductor production facilities for central vehicles were located, and they became the catalyst for the confusion of semiconductors. The Samsung Electronics, NXP and Infineon plants located in Texas, USA, suffered serious production interruptions, such as the closure of operations in February and March due to power outages and freezing of water pipes following a cold snap record. Previously, the Asahi Kasei factory was stopped due to a fire in Miyazaki prefecture, Japan in October last year, and the Renesas Electronics factory in Arabaki prefecture, Japan was stopped in January this year due to an earthquake. . Taiwan’s TSMC, the world’s largest memoryless semiconductor producing company, also complained about water shortages due to the February and March drought, suggesting the possibility of a reduction in production. The company said on day 1 that there is no discount sale, even for large orders, and announced a policy to increase the price in effect. This is a cross section showing that a dominant supplier market is forming. Few major companies dominating the memoryless semiconductor market have escaped production disruption.

The serious problem is that the shortage caused by chance has been at least several more months. This is due to the specificity of semiconductors. In the case of semiconductors, when production is temporarily stopped, a significant part of the raw material must be discarded and the factory must be cleaned. This is similar to the fact that it takes months to reactivate a cold oven. Some market experts predict that it will take at least two more months for semiconductor factories affected by natural disasters to regain their normal level of production. For this reason, the Korean government also launched the “ Future Vehicle-Semiconductor Solidarity and Cooperation Council ” early last month to respond to the disruption in vehicle semiconductor production, but is seeking a definitive solution with just the remaining countermeasures. on the fly to the level of simplifying the customs clearance process for semiconductors. I can not.

Biden’s Noim Soo? … Is semiconductor agitation used to expand national production?

Some analysts say there is another stone in the direct response from the US White House. The Biden administration, which emphasizes national priority in the economic sector while distancing itself from the previous Trump administration, is said to have planned an emergency meeting on a plan to expand domestic production of memoryless semiconductors, which will be the seeds of the future industries. like autonomous driving and artificial intelligence. The fact that the White House official presiding over the discussion is National Security Advisor Jake Sullivan makes this assumption compelling. Although the US government does not comment on the subject of the detailed discussion, foreign media such as the United States have published reports claiming that “finding vulnerabilities while intensively reviewing the semiconductor supply chain is the key to this meeting.” In fact, prior to the meeting, the US government conducted a stress test that analyzed vulnerabilities in the supply chain based on various what-if scenarios. One reason for this analysis is that the Biden administration was taking steps to expand its domestic semiconductor production capacity. An example is the American Jobs Plan, which the United States government released on the 31st of last month along with a large-scale tax increase plan. One of the pillars of this plan is that the US government and the private sector will invest $ 2.2 trillion, equivalent to 1% of the US gross domestic product (GDP), to boost the economy and restore employment. Here’s the ‘Semiconductor Manufacturing and Research Support Division (Chip Act). All investments in this sector amounted to $ 50 billion (about 56 trillion won in our money). It is an aggressive plan to invest 10% of the Korean government budget (about 558 trillion won) this year in the semiconductor sector. Of course, it remains to be seen whether such a plan will come true. It is an investment with the private sector, but it is accompanied by large government expenditures, so it must be approved by the United States Congress for the budget adjustment. In addition, there are voices concerned about the market’s tacit reaction against aggressive government intervention in certain markets, or the secondary effects of such intervention. In an interview with CNBC, Roman Schorr, an analyst at Fitch, an international credit rating agency, “The government’s policy actions are significant in the long term. However, the imbalance in supply and demand for semiconductor chips that we are witnessing is a problem in the market. “In situations such as the liquidity crises that often appear in financial markets, market intervention at the level of supply of funds From the point of view of long-term industrial strategy, government and central banks or subsidizing specific sectors is reasonable, but the government is even aggressive with the supply and demand imbalances that are often observed in the market, meaning getting involved is inappropriate or may lead to side effects By Kim Kyung-rak, Staff Reporter [email protected]

[ad_2]