[ad_1]

Completion in 2 years by investing 3.5 trillion won … DRAM production from June to July this year

Chairman Taewon Choi “M16 is the completion of a grand plan … the starting point leading to the Yongin cluster”

SK Hynix will seriously open the era of EUV (Extreme Ultra Violet) exhibition equipment for DRAM semiconductor production and accelerate memory semiconductor microprocessing.

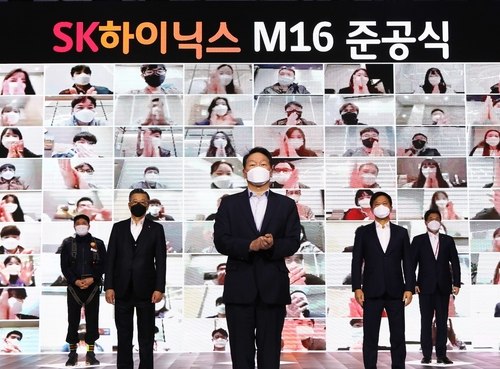

On the 1st, SK Hynix held a completion ceremony for the ‘M16’ plant at its headquarters in Icheon, Gyeonggi-do.

At the ceremony held under the theme ‘We Do Technology Opening Happiness’, SK Group President Choi Tae-won, Choi Jae-won, Senior Vice President Cho Dae-sik, SK Supex Pursuit Chairman of the Board, Park Jung-ho, SK Hynix Vice President Jang Dong-hyun, SK President Lee Seok-hee, SK CEO Hynix, and Ha Young-gu were appointed. 16 key figures attended, including outside directors.

Members and employees of the partner companies participated in the event without touching (not face to face) via video connection.

President Tae-won Choi said: “When we said we were building the M16 two years ago, when the semiconductor economy was in recession, there was a lot of concern.” However, as the semiconductor recovery cycle is talked about, the bold decision we make during tough times will create a bigger future. It made me dream, ”he said.

President Choi said: “M16 is the completion of the grand plan that the company has come up with and will continue to be an important symbol as a starting point for the ‘Yongin Cluster’ in the future.”

The Yongin Semiconductor Cluster Project is to build a next generation memory production base in Wonsam-myeon, Cheoin-gu, Yongin, by Yongin General Industrial Complex Co., Ltd., and SK Hynix will invest around 122 billion won to build a semiconductor. production complex.

The first SK Hynix EUV (Extreme Ultra Violet) exhibition equipment will be introduced in the M16 plant completed that day.

The EUV process uses an extreme ultraviolet light source in semiconductor photoprocessing, and its wavelength is shorter (less than one-tenth) than conventional argon fluoride (ArF) light source, which is advantageous when a microcircuit pattern is implemented in a semiconductor. It can also increase productivity.

Since the start of construction of the M16 in November 2018, SK Hynix has invested a total of 3.5 trillion won and 3.34 million people to complete construction in 25 months.

M16, which will mainly produce DRAM products, boasts the largest scale among SK Hynix’s domestic and foreign production facilities.

The construction area is 57,000m2, the size of 8 soccer fields, and is 336m long, 163m wide and 105m high, reaching the 37th floor of the apartment.

The total investment cost, including equipment, is approximately 20 trillion won.

It is known that two EUV equipment will be installed in the M16 during this year and through this equipment the fourth generation of EUV 10-nano class (1a) DRAM application products will be produced after the second half of the year.

Mass production through general equipment other than EUV starts from June to July.

SK hynix plans to grow this plant as a next-generation growth engine based on state-of-the-art infrastructure.

President Lee Seok-hee said, “The completion of the M16 is significant because it is the first achievement of the ‘future vision’ announced by SK Hynix at the completion ceremony of the M14 in Icheon in 2015.” base level of production that it contributes ”.

The operation of SK Hynix’s M16 plant is expected to intensify competition for next-generation DRAM production using microprocessing in the memory semiconductor industry.

Samsung Electronics completed the customer assessment by applying the EUV process to first-generation 10-nano (1x) DDR4 in March last year, and plans to mass-produce EUV equipment from DDR5, the next-generation DRAM that will be introduced at the second half of this year and LPDDR5 for mobile devices.

Micron Technology of the United States, the world’s third-largest DRAM maker, announced in late January that it had shipped the world’s first fourth-generation 10nm next-generation DRAM.

Existing argon fluoride (ArF) equipment was used for this product, not EUV equipment.

/ yunhap news