[ad_1]

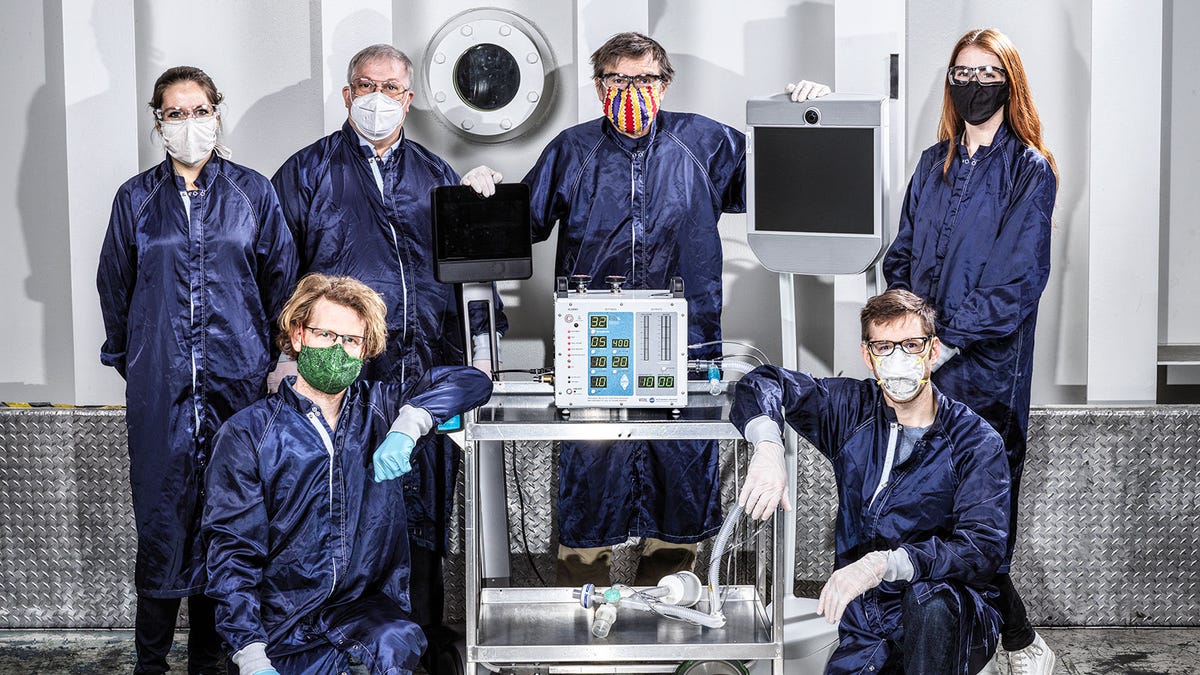

This is VITAL, a prototype respirator designed specifically for quick and easy mass production. Developed by NASA engineers, the device could alleviate the current supply shortage both in the United States and around the world, as the covid-19 pandemic keep going.

NASA has a lot of brain power available among its members, and it’s great to see the space agency take advantage of it during this difficult time.

“We specialize in spacecraft, not medical device manufacturing,” said Michael Watkins, director of NASA’s Jet Propulsion Laboratory (JPL), at a release from the space agency. “But excellent engineering, rigorous testing, and rapid prototyping are some of our specialties. When the people at JPL realized that they might have what it takes to support the medical community and the community at large, they felt it was their duty to share their ingenuity, experience and drive. ”

Their efforts have resulted in a high pressure ventilator or respirator called VITAL, which stands for Locally Accessible Ventilator Intervention Technology. Developed in just 37 days, the device still needs approval from the United States Food and Drug Administration (FDA), but it could certainly ease the pressure in hospitals and other healthcare settings during the covid-19 pandemic. .

According to Dave Gallagher of JPL, it is estimated It could cost $ 2,000 to $ 3,000 to produce the respirator, while, for example, General Motors is also producing “low-cost” respirators, but they are priced at about $ 16,000.

That respirators are scarce in the United States and around the world is frustrating, but also understandable. What did you say Canada’s director of public health, Theresa Tam, “if you’ve seen a pandemic, then you’ve seen a single pandemic,” meaning that they are all unique in terms of disease pathology and progression. This disease particularly affects the lungs brutally, and hence the need for more respirators than are available.

Of course, respirators are not the only necessary solution. The recent statistics York City researchers show that 88% of covid-19 patients connected to respirators succumbed to the disease. That is discouraging, but it is still a material impact in terms of total lives saved.

VITAL could help alleviate shortages because it can be built and maintained faster and easier than conventional designs. It requires fewer components, many of which can be purchased through existing supply chains. VITAL also features a flexible format, which means it can be adapted for multiple healthcare settings, such as makeshift hospitals, basketball courts, convention centers, hotels, or anywhere else where patients can be treated.

Like other respirators, VITAL will require that patients be sedated and a tube inserted into their airways. After this, VITAL does the rest, providing mechanically assisted ventilation for patients who are no longer able to breathe on their own or are being affected by a serious condition called acute respiratory distress syndrome.

VITAL has a limited useful life: the machines should not be used for more than several months. Traditional hospital respirators, by comparison, can last for years. NASA said VITAL is a solution made to help with the covid-19 pandemic.

The next step is for the respirator to be approved by the FDA, which NASA says seems likely given that the device performed well during tests at the Mount Sinai Human Simulation Laboratory. Additionally, NASA is using the emergency fast-track for approval, in which the US government regulator can approve the concepts in days, rather than years.

This NASA solution to the scarcity of respirators is not the only one. A group of MIT volunteers, for example, recently came up with a design, called the Spiro Wave, that has been approved by the FDA.