Sony’s Japan-based manufacturing facility will be a huge asset when it begins producing next-gen PS5 consoles alongside the current line of PS4s.

SEE GALLERY – 2 IMAGES

Image credit: Nikkei Asian Review

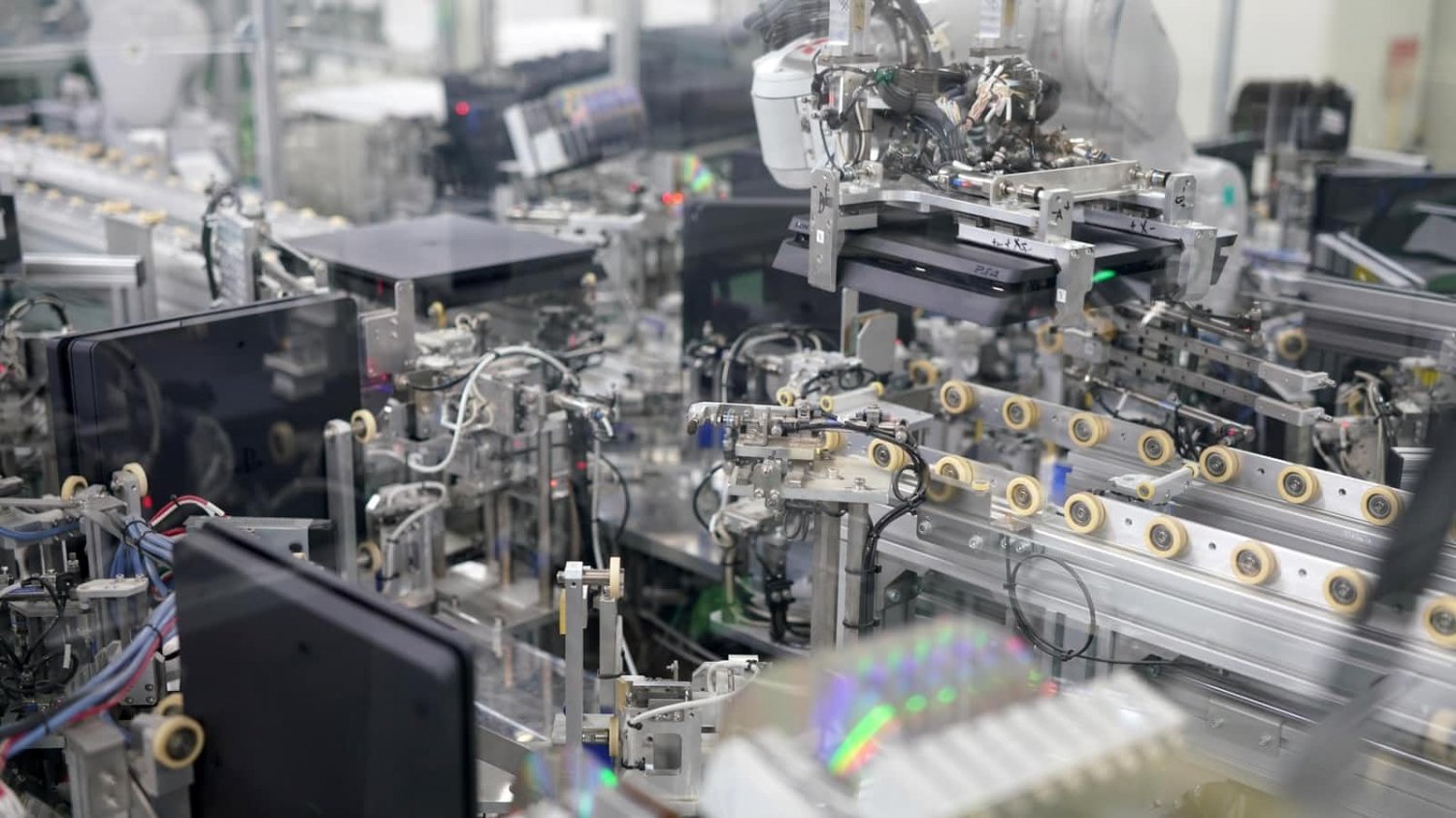

A recent report from Nikkei Asian Review sheds light on one of Sony’s little-known advantages in the home arena: an ultra-efficient assembly line that can produce two PlayStation 4 consoles every minute. The Kisarazu-based plant is wholly owned by Sony and owes its rapid productivity to a team of 32 specialized Mitsubishi robots operating a 100-foot assembly line. The plant has helped produce all generations of PlayStation hardware since PS1 was released in 1994.

The installation is almost fully automated, and there are apparently only four people on the line at any given time. Robots do most of the assembly, including twisting cables and threading them through small gaps, while workers simply feed the unfinished consoles into the straps and then package the finished products.

Image credit: Nikkei Asian Review

Apparently Sony started using this strategy in 2019, and it should help maximize production efficiency with the Next generation playstation 5 console alignment.

Starting this year, Sony will manufacture and produce four different PlayStation consoles in two generations: the digital edition of PS4, PS4 Pro, PS5 and PS5.

Last update: July 4, 2020 at 08:56 pm CDT

.