[ad_1]

(Central News Agency reporter Chen Yunyu, Taipei, 20) Czech Senate President Vitzi, defying the CCP threat, led a delegation to visit Taiwan in late August. To thank Vitzi for supporting Taiwan, an automation equipment manufacturer in Tainan announced a gift of 5 mask production lines before leaving Taiwan. . After more than three months of intense bilateral negotiations, two of the production lines will begin shipping this week.

Dong Jian’an, who has about 25 employees, has ceded the Miloš Vystrčil mask production line to the Czech media. Vystrčil has also explained to the local media the progress of coordination with the relevant units of the Czech government, the Czech Chamber of Commerce of Taiwan and Dong Jian’an. Witzi has convened at least three bilateral videoconferences between the Czech Republic and Taiwan for this case, and Ke Liangrui, the representative in the Czech Republic, also participated.

This donation seems simple, but there are many factors that have not been fully implemented. The complex internal politics of the Czech Republic, the high degree of independence of various government authorities, the legal restrictions of the EU and the Czech Republic, and the absence of official relations between Taiwan and the Czech Republic are just some of them. Article. However, as Vitzy said at a Foreign Ministry press conference on September 3, “You can find a way if you have the heart.”

A 40-foot container that can accommodate two mask production lines is scheduled to ship this week. Guo Lilin, general manager of Dongjian’an, told the Central News Agency that the company will start dealing with shipping matters tomorrow. The containers will go to sea from the port of Kaohsiung, arrive in Germany about 40 days later, and then be transported by rail to Prague, the capital of the Czech Republic.

Guo Lilin said that the donation case adopts a “business-to-business” (B2B) model, and Taiwanese and Czech companies coordinate and solve various derived costs. According to the current plan, 4 of the 5 production lines will be run by InoCure, a Czech R&D manufacturer of nanomaterials and equipment. InoCure will establish a joint venture with Good Mask, one of the largest Czech mask manufacturers, to establish a social enterprise “European Center for Research and Development of Respiratory Protective Equipment” (ECVVR) in Prague. ECVVR will allocate 5% of the finished products to the Czech Senate and other agencies for allocation to demanding units such as medical institutions. ECVVR does not have the participation of Taiwanese capital.

The 3D masks manufactured by the Taiwan-Czech cooperative production line are of higher quality than general medical masks, similar to N95, and are called respirators in English.

According to the information provided by Dongjianan, if the 4 production lines are fully open and operated for 20 hours a day, the total daily production capacity will reach 160,000 pieces, which is 4/5 of Good Mask’s current daily production capacity. . This means that under ideal conditions, the fully automated team in Taiwan will be able to produce some 8,000 3D masks a day for free use by the Czechs.

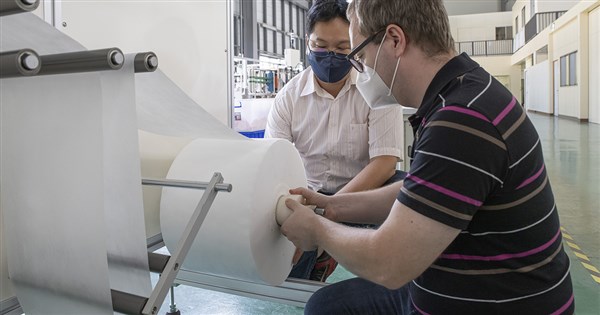

To understand the operation of the equipment and test the compatibility of materials and equipment, InoCure CEO Matej Buzgo and technical expert Miroslav Doupník arrived in Taiwan in early December. They were quarantined in a hotel in Taipei for 14 days, and then they studied and studied in Dongjian’an for about a week. They then went to Taipei on the 18th to visit the Textile Industry Research Institute and the Czech Economic and Cultural Bureau, and then went to the Czech restaurant Divadlo in Taipei to celebrate the trip to Taiwan. Everything went smoothly and he returned to the Czech Republic on the 19th.

Compared to other partners who have come to study at the factory and are mostly Taiwanese, Guo Lilin said that Buzgo and Dopnik like to “find the roots”, not only paying attention to physical details, but also to logic. layout, and all links are Implement verification. Guo Lilin said he was “very relieved” to hand over the equipment and technology.

Guo Lilin emphasized that automation equipment is not candy or cookies. “It is good to have a separate mind.” Whether it’s use, maintenance, etc., technology is required; the contractor is untrained and the future utilization rate of the equipment is worrying. “I can also donate things and leave them alone and let the other party distribute them. I don’t have to spend so much time in meetings and exhaust myself. But if things are for people who can’t use them well, things that are useful will become useless. Even if it becomes a burden, it will not only affect my reputation, but also Taiwan’s image. “

Therefore, he insisted that the company party must have relevant careers and must come to Taiwan for training.

Guo Lilin said that his original intention was to thank the president of the Senate who represented public opinion and helped the Czech people, not to donate to the Czech government. Therefore, all arrangements should be based on the people who maximize substantial benefits and help the most.

He stressed that only the undertaker who is capable of “self-reliance” can truly contribute to society, and the path to public welfare can go a long way. In addition, it hopes to open new opportunities for technological and industrial cooperation between Taiwan and the Czech Republic, and even between Taiwan and the European Union. He said, “I and several colleagues often think about the next step for the machine tool industry and the Taiwanese economy.”

Subscribe to the “Good Morning World” newsletter to master 10 things about the world in 3 minutes a day

subscription

He said that the global situation is changing rapidly and that the epidemic and existing technological competition continue to pose challenges to the industry. He is about to retire, but hopes that his profession and experience will be useful for the future of Taiwan.

Regarding the phase-out of the fifth production line, Witzy has told the Czech media on several occasions in recent days that he currently plans to adopt a “government-to-government” (G2G) model. He agrees that handing over most production lines to private companies is the best arrangement to avoid competition between government and private companies or private subsidies and acceptances, and “the government is usually the worst manager.” However, it is understood that there may be variables in planning related to G2G. (Publisher: Lin Shuyuan, Huang Guolun) 1091220