[ad_1]

Tesla’s 2020 Battery Day started today. Musk officially announced that Tesla will begin manufacturing batteries and build a new super battery factory. New batteries are expected to greatly increase battery life and become cheaper. Tesla will have the opportunity to launch 2 A $ 5,000 civil electric car.

Before Battery Day, Tesla held a general shareholders meeting and some highlights were put together for interested readers.

“Tesla should be the only wholly foreign-owned company in China. We built a super factory in Shanghai from a wasteland in 15 months, driving all sales,” said Elon Musk. Today, it has successfully profited for four consecutive seasons (GAAP) and continues to generate positive cash flow. He is now working hard to bring the Berlin Super Factory and Austin, Texas Super Factory online to continue making the company more financially healthy.

2020 is a crazy and strange year. Relying on the assistance of the team, consumers and investors, in the last year, when the global auto industry has fallen into negative growth, Tesla is the only car factory that is growing.

In the end, it may be in response to other recent rumors about the new Nikola electric car startup. Musk mentioned: “It is not easy to design a prototype car, but it is about ten times difficult to design a factory and a production line that can actually build a car. Times or even a hundred times. These production lines look alike, but we are committed to make each production line more efficient. This is the fundamental competitiveness that allows us to continue growing. “

It is a rare operation for technology companies to elect a general meeting of shareholders before a global press conference, and the thinking behind it is left to the imagination of readers.

Featured: Super Battery Factory

Musk threw two big goals in the opening game. First, to achieve the goal of the Tesla establishment and create sustainable energy sources, electric vehicles require a hundred times more power and batteries than current ones. From the perspective of Tesla’s complete production line, the total battery capacity should be Going from the current 0.06 TWh to 10 TWh, this is Tesla’s new goal. T stands for Terra, which is a thousand times bigger than Giga.

If according to the current production model, Tesla needs to build 135 Gigafactories, which would require approximately 2 million employees and a construction budget of $ 2 billion, it seems not feasible.

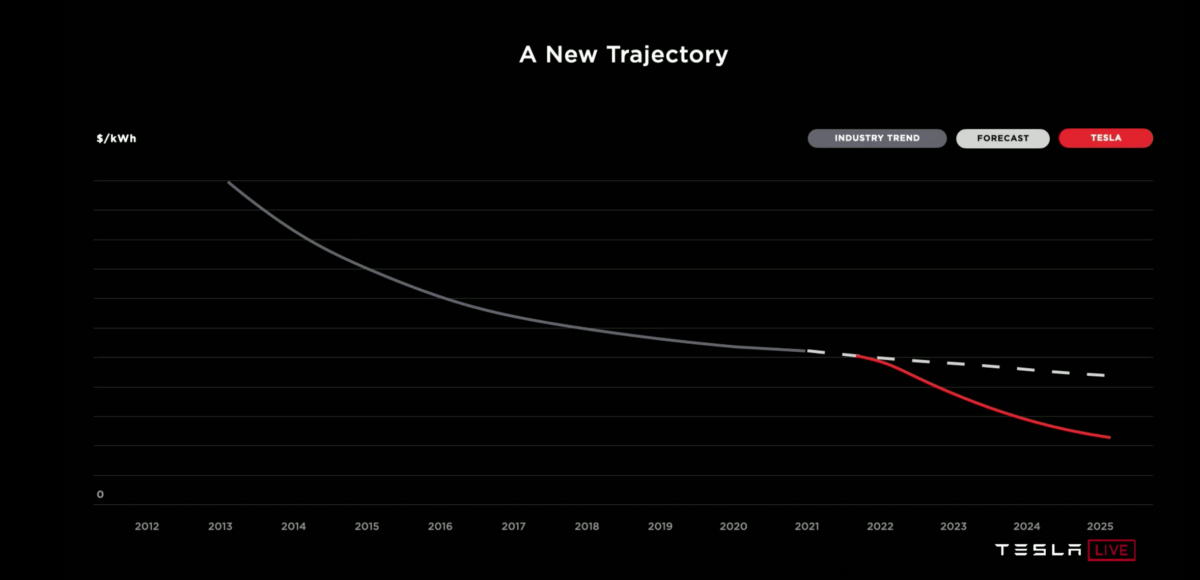

The second goal is to make cheaper batteries. Although the electric vehicle market is growing, electric vehicles are not yet a civilian option, but current battery manufacturing costs are not falling as expected.

Therefore, Tesla’s solution is to create your own“Super Battery Factory”Responsible for battery design, production, electrode materials, etc. to speed up battery production and reduce manufacturing costs. Tesla expects that within a year, the production of the new battery plant will reach 10 GWh and continue to grow.

▲ Self-made comprehensive batteries will provide three benefits.

From 2008 until now, the capacity of the same-size battery has grown by 50%, but for Tesla, this growth rate is far from sufficient. Musk introduced five new manufacturing processes for Tesla’s self-made batteries. First of all, these technologies are extremely difficult new inventions. Due to space, we can’t write most of the details, but that doesn’t mean these technologies are simple.

▲ Tesla’s self-made battery will make a big leap in performance.

Tesla’s new self-made battery design simplifies the lithium-ion battery winding method and shortens the movement distance of electrons in the battery. The new battery provides better capacity and efficiency.

▲ The new battery winding method simplifies the current manufacturing process for lithium-ion batteries.

In the battery manufacturing process, the process of various metal materials, from powder to sheet, is very complicated. Tesla designed a new solvent press machine, which completes the stirring, melting, drying and molding processes in a single machine. Capable of achieving ten times the manufacturing efficiency, but “really difficult, I can only say that we are about to make it successful, but not that fast,” Musk said.

Even the great talkative Musk speaks so conservatively, you can imagine how difficult this is.

In the battery assembly part, Tesla will redesign all the equipment on the production line to create a battery assembly highway, which can increase the assembly speed by seven times. At the same time, the factory will occupy a smaller area, allowing one factory to reach other battery factories. Several times more than the production capacity.

“In the future, all car factories can have long-range electric vehicles and can also have autonomous driving, but Tesla wants to become the best manufacturer in all respects,” Musk said. (Mystery Voice: Where is your tolerance?)

While improving efficiency, another mission of the Tesla battery factory is to reduce energy consumption and the carbon footprint of the manufacturing process. Your goal is 10%, not 10%, but to become 10% of the current power consumption of the battery factory. “Our new mid-range goal is By 2030, reach a battery production capacity of 3 TWh per yearBut some of them will be purchased from cooperating battery manufacturers. Musk said.

On the content side, the metallic materials used in lithium-ion batteries determine their price and performance. In the anode part, Tesla will introduce a large number of silicon anodes to make batteries cheaper and increase their useful life by 20%. The cathode material, as Musk said earlier, nickel is the metal Tesla will value the most in the future. They will develop batteries with different nickel content and provide batteries with different energy densities, so that a variety of vehicles can have the best energy price ratio. .

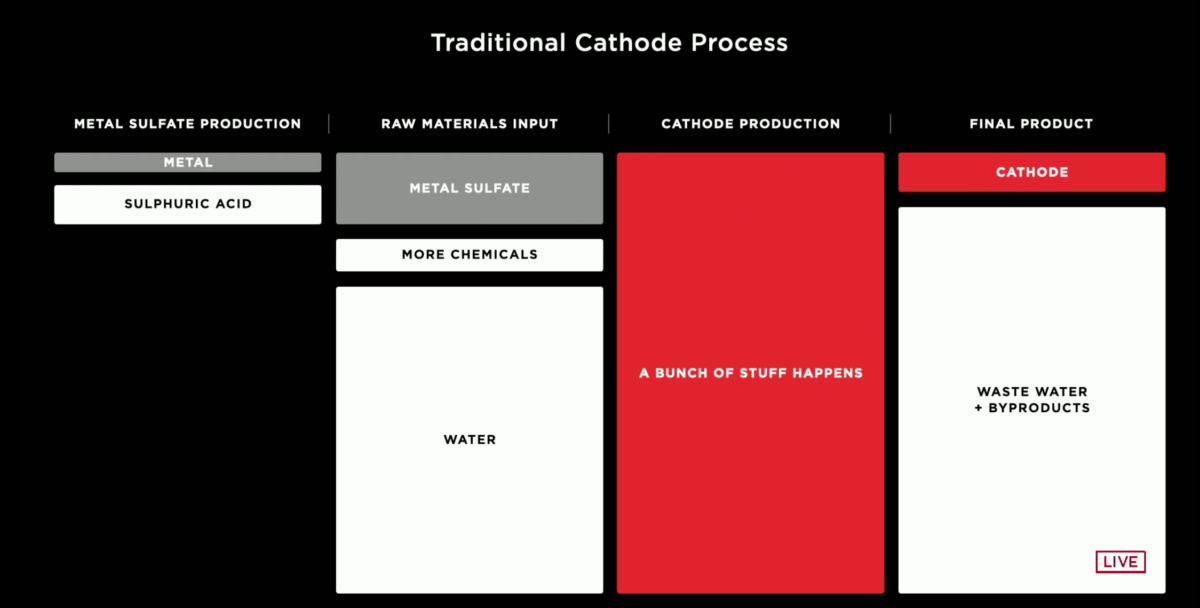

▲ In the lithium-ion battery cathode manufacturing process, Tesla plans to redesign the production line and eliminate wastewater.

In the battery cathode manufacturing process, 35% of the cost comes from the “manufacturing process”. Tesla wants to reduce labor by redesigning the production line and reducing manufacturing costs by 76%. At the same time, it redesigns the water cycle in the process to replace the original. Waste water is reduced to zero.

After the super battery factory, there is also the Tesla mine.

With the massive increase in electric vehicles and batteries, the prices of various metallic materials are also rising, and may even become a bargaining chip in international politics. To avoid the out-of-stock situation, Tesla not only had to manufacture its own batteries, but also studied its own mining. They acquired 10,000 acres of land in Nevada and used their self-developed mining machines to exploit the rich lithium mines. Tesla estimates that the production from this mine alone is sufficient for all vehicles in the United States to be replaced by electric vehicles.

Another key benefit of self-extraction is that Tesla can fully control the environmental impact of the process, and there are currently many controversial labor rights issues.

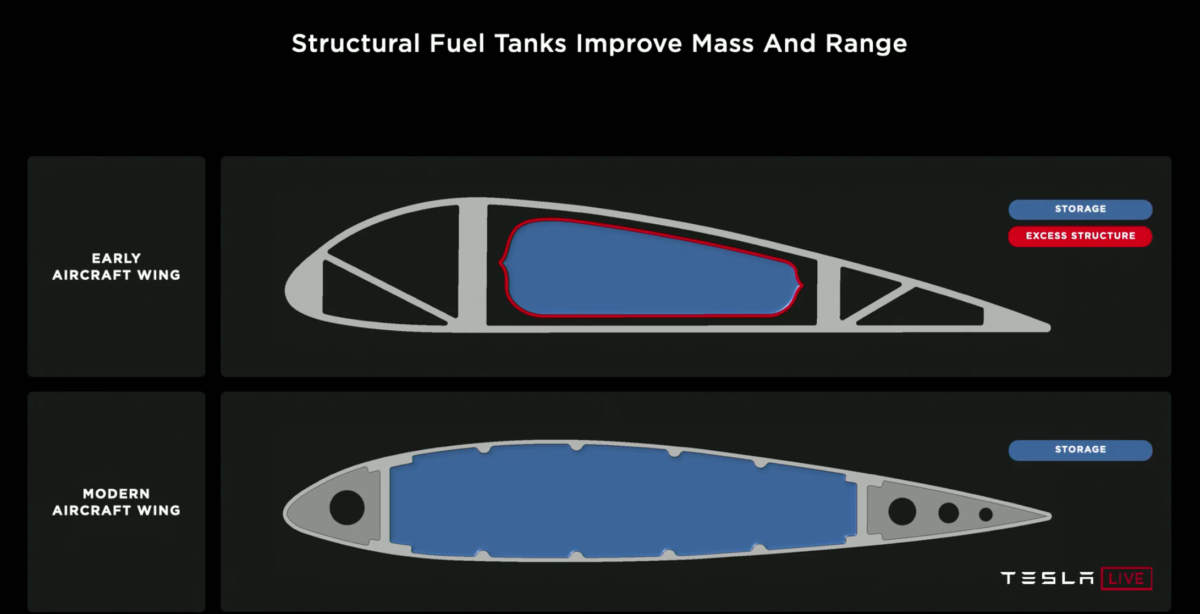

In the casting process of a Model Y part, assembly parts are simplified, cost is greatly reduced, and manufacturing speed is increased. From this point, Tesla came up with a new concept borrowed from the airplane: the battery becomes the body of a car, called structural batteries.

▲ Aircraft fuel is stored in the wings and Tesla translated this concept to the body.

During the body casting process, the machine “sticks” the battery pack directly to the body, with a carbon fiber backing to form a honeycomb structure, saving the structural space of the components surrounding the battery pack. and improves the body’s resistance.

More importantly, through this method, the time of the entire manufacturing process can be shortened even more by 10%, the new space created can be charged with more batteries, and the battery life can be increased by approximately 14%.

▲ The Tesla battery factory will greatly reduce the price per kilowatt-hour of electricity, beating the original analysis and prediction.

“Since I founded this company, my dream is to build an electric car that is cheaper than a fuel car.” Musk said Tesla’s self-made battery factory will give Tesla a chance to launch 25,000. A new civilian car with dollars.

At the end of Battery Day, Masik also announced that Tesla’s most powerful car at the moment, the “Plaid Model S”, will be available for pre-order. This vehicle, which set the best record in history at the Laguna Circuit last week, can start in 2021. Delivery.

Quick experience

Simply put, Tesla has developed a host of automation technologies during car construction in recent years. Now they want to bring these technologies into the battery manufacturing process and introduce new materials, new processes, and new technologies all at once. This is the history of the development of electric vehicles. Important events. If Tesla can achieve these goals, we will have a chance to see Teslas under NT $ 1 million by 2030, maintaining at least the same level of performance as the current Model 3.

However, each of the above process improvements is a huge challenge. Musk has proven his success many times, but he has also set many bragging records. It is not too optimistic whether these goals can be achieved. But the truth is that the most nervous company in the world is not Toyota, or GM or Flowserve, but Panasonic, Tesla’s long-term battery partner.

(Image Source: Tesla)

[ad_2]