SpaceX seems to have successfully completed one of three key tests between a new Starship prototype and the next rocket hop.

Known as a cryogenic proof (“cryo proof”), signs are currently pointing to a success on the first attempt of Starship SN6 – although an hour or two past the end of the scheduled test window. The proof was scheduled between 8 a.m. and 5 p.m. CDT (UTC-5) on August 16 with identical backup windows on Monday and Tuesday in the event of a cancellation or delay. Fortunately, in a breath of fresh air after many Starship SN5 test delays, SpaceX had no such need.

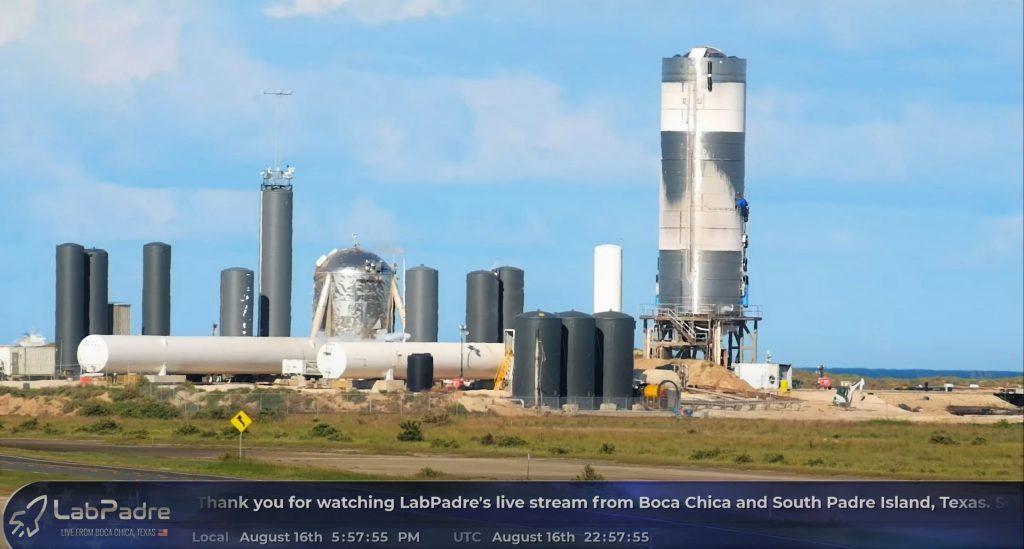

With the help of local sheriffs, SpaceX closed the highway at 10:15 a.m. and hit Starship SN6 with ambient temperature gas (probably nitrogen) about half an hour later. As usual, the company took its time, while the prototype Starship was effectively killed for the first time. About 2.5 hours later, the Starship began to vent visibly for the first time, as it operated dozens of valves to maintain safe tank pressures.

To perform a cryogenic pressure test, SpaceX effectively performs a wet dress rehearsal (WDR) – a test that simulates a full take-off stream short of liftoff – without engine installed. To prevent leaks or fuselages from turning potentially catastrophic during what is often the first major test of a prototype, SpaceX Starship charges with liquid nitrogen (LN2) instead of liquid methane and oxygen propellant. During that process, Starship’s thin steel skin will soon sag to arctic temperatures, and become cold enough that it later freezes the water vapor from all the surrounding air where it comes in contact.

At 13.00 local time, the first sign of that frost coat appeared, but remained a sliver before disappearing at 14.00. Starship SN6 then hung for an hour before restarting test activities. Nearly 5:40 p.m., nearly an hour after SpaceX’s August 16 window was about to close, frost appeared on the hull of Starship SN6 and quickly crept up the side of the massive rocket.

Starship SN5’s own cryo-test test – completed on June 30 – debuted apparent upgrades to SpaceX’s South Texas launch facilities, loading the rocket with hundreds of thousands of gallons of LN2 in 15-20 minutes. The ability to load very large amounts of cryogenic fuel will be critical for SpaceX, as Starship’s efficiency will decrease substantially as its propellant heats up. Along those lines, Starship SN6 became the second prototype to be rapidly charged with liquid nitrogen, going from almost low to almost complete in ~ 15 minutes.

SN6 struck the next hour as so loose and SpaceX opened the road and had a team back on the road to view the rocket at 7:40 p.m. At one point during the test, SpaceX apparently activated hydraulic arms attached to Starship’s engine section to simulate the tension of Raptor pressure under cryogenic loads. However, SpaceX was apparently pleased with the results of the first cryo-evidence of Starship SN6 and went ahead with the cancellation of two backup windows planned on 17 and 18 August – a consistent sign that things were going exactly the same as very wrong.

In the case of SN6, nothing was clearly wrong or otherwise during the cryo-evidence, pointing to a successful test. If so, SpaceX will begin removing the hydraulic Raptor simulator to install an actual Raptor engine and will plan road closures for a heavy static fire test. Before that actual Raptor ignition test, SpaceX may choose to perform a wet dress rehearsal (WDR) on its own or partially test Raptor by igniting its preburners to spin its turbopumps at the moment. The company was also able to integrate both of these predecessor tests into the same window as the static fire itself.

If those tests go according to plan, Starship SN6 could be ready for SpaceX’s second full-scale hop sometime just a week (or less) later. CEO Elon Musk says the company’s current goal is to conduct multiple Starship tests until the process is fast, smooth and consistent.

Check out Teslarati’s newsletters for quick updates, straightforward perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes.