[ad_1]

It has been several months since the new coronavirus began to threaten the world. Scientists are still looking for solutions, but so far nothing is effective. The vaccine is also slow to arrive and when it is announced it will not be available to everyone.

Now comes an incredible discovery from Brazil! A plastic that can inactivate the new coronavirus in minutes.

Plastic can remove 99.84% of coronavirus particles after two minutes of contact

The accumulated number of people infected by COVID-19 has already exceeded 29 million and the number of deaths is already 936 thousand. A solution, be it a vaccine or a treatment, is needed to fight COVID-19. A study published on Tuesday shows that a plastic is capable of eliminating 99.84% of the coronavirus particles after two minutes of contact.

The plastic, made of polyethylene and with microparticles of silver and silica (silicon oxide) in its structure, managed to eliminate almost all the particles of the new virus after only two minutes of contact.

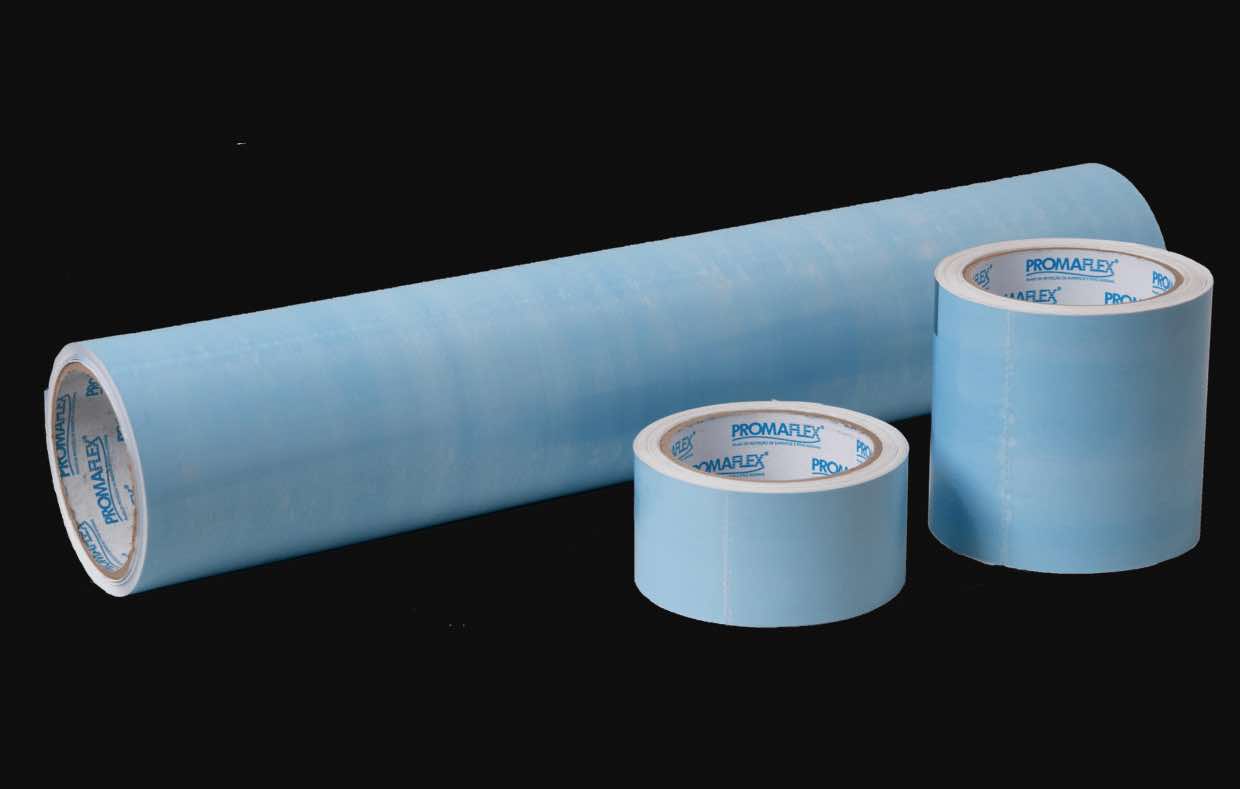

This plastic was launched by Promaflex, a company specialized in the production of this type of film. The material was developed by the company Nanox with the support of the innovative research program for small companies of the São Paulo Research Foundation (FAPESP).

For the study, samples of materials with and without silver and silica microparticles incorporated into the structure were used, which were kept in direct contact with SARS-CoV-2 at different time intervals.

After the stipulated deadlines, the new coronavirus present in the material samples was collected and contacted with Vero cells -type of cell line used in microbiological cultures- to evaluate the capacity for infection and multiplication after exposure to the plastic. adhesive, reveals Lusa.

The manufacturer of the plastic with the additive recommends its use for up to three months, to avoid wear of the material due to excessive contact. The cling film is the second plastic material with silver and silica microparticles marketed by Nanox, which developed a reusable mask made with a flexible plastic and the additive applied to its surface.

Nanox has also applied silver and silica microparticles to fabrics for the development of anti-COVID-19 garments. In fabrics, the microparticles of silver and silica are impregnated on the surface through a process of dipping, followed by drying and fixing, called "pad-dry-cure".

[ad_2]