[ad_1]

Aidas Simanavičius, manager of the Sotus derlius company, which offered this lower price, explains: that price is not too high, taking into account the costs incurred by the carrier.

Currently, the Health Emergency Center (ESSC) has temporarily suspended the transport contract with this company.

Remigijus Mielinis, director of the Armila company, which handled the logistics of the first batch of vaccines in Lithuania, says that the whole process seems incredibly simple just without knowing the details.

There are two people working

The choice of a logistics service provider has raised many questions, as the winning company of the contest, crucial for universal vaccination, has no experience in pharmaceutical and vehicle logistics.

Furthermore, it employs only 2 people.

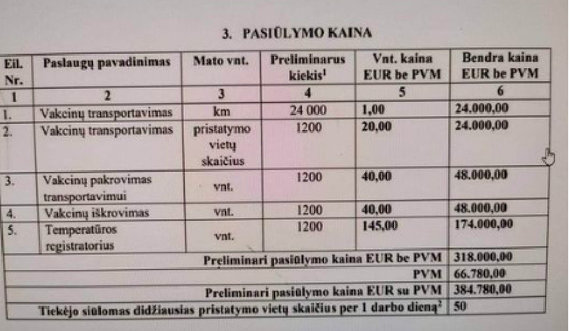

After the LRT announced the offer of the company Sotus Cosecha, which won the vaccine transport competition, it was examined down to the smallest detail.

It is incomprehensible that the state should pay the company up to 48 thousand. EUR for the vaccine load and the same amount for the vaccine discharge.

Screenshot / Saturated Harvest Price Offer

Aidas Simanavičius, the head of Sotus Harvest 15 minutes He explained that this price only seems high from the outside.

The component of the price of loading and unloading is the costs incurred by the company, and indeed many of them: dry ice and other necessary measures.

Sotus Harvest won the vaccine transportation competition by offering the lowest price.

In this way, it outperformed competitors, including Armila, which also participated in the tender and transported the first batch of vaccines in Lithuania.

The vaccine route in Lithuania

Remigijus Mielinis, Director of Armila 15 minutes revealed that vaccine transportation is an expensive and carefully planned process.

It is easy and simple to appear unconscious to the uninitiated.

The vaccines delivered to Lithuania by the manufacturer begin their journey in the warehouse of the Health Emergencies Center.

Not only are vaccines stored here, but all necessary tools for vaccination (solutions, syringes, patches, disinfectants) must also be delivered to hospitals.

The Armila director says that for this reason, two trucks are sent on the trip, one with vaccines and the other with all the necessary equipment.

Two tractors are also needed so that in the event of an unforeseen event on the road, the delivery process is not interrupted and the cold circuit is properly maintained.

Two tractors are also needed so that in the event of an unforeseen event on the road, the delivery process is not interrupted and the cold circuit is properly maintained.

Armila transports vaccines by two routes: Nemenčinė-Vilnius – Panevėžys – Šiauliai and Nemenčinė – Kaunas – Klaipėda.

These cities are home to large national hospitals responsible for the follow-up vaccination process.

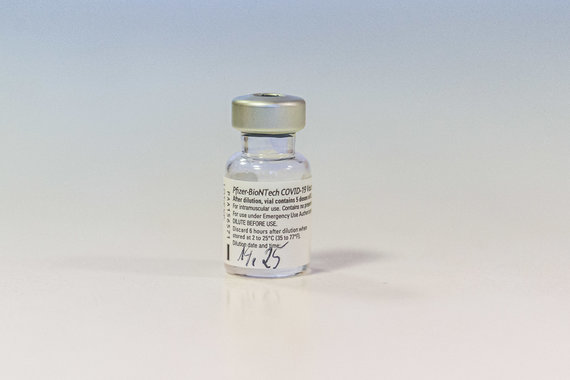

Vaccines are available from Pfizer especially finished in boxes with dry ice. Contain the manufacturer finished sensors to monitor temperature changes during transportation.

ESSC personnel who have taken over a shipment must be present at it. finished the sensor presses the “stop” button – then the temperature information is automatically transferred to the Pfizer center, where the message about the shipment’s delivery is recorded.

Photo by Scanpix / Pfizer / BioNTech Coronavirus Vaccine

The vaccine manufacturer must send a confirmation through the Lithuanian branch of Pfizer that the shipment has been successfully delivered.

The Pfizer representative office in Lithuania also sends temperature data sheets to the ESSC, which must be carefully examined to ensure that the cold circuit has not been damaged.

Lasts a few days

The journey of the vaccine to the warehouse in Lithuania takes about three days.

After ensuring that the transport to Lithuania has been carried out correctly, the manufacturer’s vaccine finished The boxes are loaded into special ultra-low temperature freezers at the ESSC warehouse, which takes only 5 minutes to handle.

According to the manufacturer, it is essential that the vaccines remain in the freezer for at least two hours after transshipment.

According to the manufacturer, it is essential that the vaccines remain in the freezer for at least two hours after transshipment.

After this time, vaccine carriers distribute the load separately to each hospital as needed.

The transport company is prepared for dry and special ice in advance. finished boxes.

One of these boxes contains 5 boxes of Pfizer vaccines.

„Reuters“ / „Scanpix“ nuotr./covid coronavirus pandemic lithuania

“Knowing the size of the order, it is necessary to calculate the amount of dry ice, since it depends on the size of the vaccine box and the number of doses. Approximately 20-30 kg of dry ice is required per insulated transport box.

Refrigerated containers are prepared in advance. They must be frozen. Only with that can we get there, ”says R. Mielinis, director of the Armila vaccine transport company.

After filling the vaccines with ice, separate, already sending data in Lithuania, finished Sensors

Upon arrival at the hospital, vaccines are discharged, along with all necessary vaccinations.

Refilling vaccines in hospital freezers also takes only five minutes.

Once the boxes are opened, the vaccines are removed and stopped. finished sensor.

His testimony is recorded by the medical institution and the logistics company, which then sends the data to the ESSC.

Carried the first batch

“We already transported the vaccines, the first batch that arrived before Christmas. So we agreed with the ministry. This is what many of our companies do: we cooperate with the American company World Courier. She is the one who specializes in ultra-low temperature transportation. Our company deals more with organizational issues and the necessary means of vaccination, and here is the “World Messenger”, the transport of vaccines, “says R. Mielinis about the transport of the first batch of vaccines in Lithuania.

A consortium of the two companies also participated in a competition for vaccine transport announced by the ESSC, but it was won by Sotus Harvest, which offered a lower price.

“It just came to our knowledge then. When I read the press, I have the impression that the whole process of transporting vaccines seems very simple for people. When everything happened at Christmas, nobody thought about such details that we had to negotiate with people. so that they would not stay with their families during the holidays, but would work and transport vaccines, ”says R. Melins of behind the scenes – the scenes work.

After all, when things happened at Christmas, nobody thought about such details that we had to negotiate with people so that they would not stay with families during vacations and work and transport of vaccines.

Armila’s boss says that transporting vaccines is a challenge for all participants in the process, because no one has encountered such complex logistics so far.

Reuters / Photo by Scanpix / Vaccine transport

“We need to calculate very precisely how much dry ice will be needed. However, it must already be vaccinated. Also, it is necessary to transport very precise quantities. Imagine that you need to bring ten to transport thirty boxes of vaccines finished boxes and approximately 150 kg of dry ice.

Then you need to put everything together correctly, place the sensor correctly so that it does not turn off. Everything must be done very carefully to avoid mistakes. Each dose is very expensive, everything must be done in a very responsible way ”, says the director of the company.

Complicated transport process

Transporting vaccines to countries around the world is a great challenge.

The high cost of vaccine loading and transportation services is due to the fact that the so-called cold chain must be maintained during transportation.

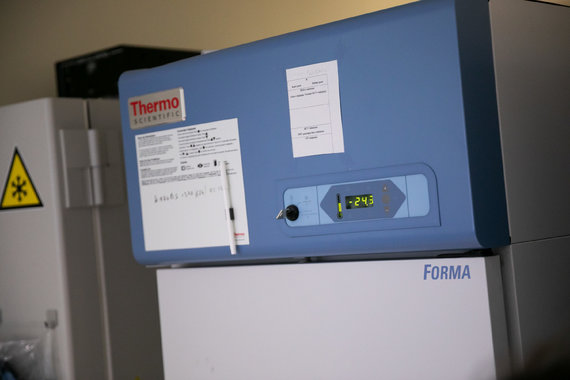

BioNTech and Pfizer vaccines should be shipped and stored at temperatures as low as -70 to 80 degrees (not less than -70 degrees Celsius) and Moderna vaccines should be stored at -20 ° C or below.

This requires special freezers and dry ice for transportation.

Sigismund Gedvila / 15min photo / Vaccine refrigerator

They must be transported to medical institutions very urgently, within a certain period of time, constantly maintaining the required cold temperature during transportation.

Transport must be specially prepared for this. It must be equipped with special refrigeration equipment.

Adequate conditions must be guaranteed throughout the chain, both for the loading of vaccines from the manufacturer to road transport, as well as for their storage in the terminal, as well as for their air transport to the final destination and during storage.

The contract has been suspended

The ESSC has suspended the highly dubious COVID-19 export contract with Sotus Harvest.

Before the pandemic, the company produced dumplings and the ESSC signed a contract with the company to ship the vaccines.

The value of the contract is 462 thousand euros.

The company managed to win an important tender by offering a price 70 thousand euros lower than the closest competitor.

The contract was suspended after an incident in which the transport of a shipment of vaccines reduced the cold and there was a risk that it would be damaged.

The vaccine was transported by a Sotaus harvest subcontractor, Radusa, whose representatives explained that there was an error in the loading of the vaccine due to the human factor.

The vaccine has not been damaged, but the reliability of the carrier has been questioned.

[ad_2]