[ad_1]

Apollo 17 astronaut Harrison Schmitt collecting a soil sample, his spacesuit covered in dust. NASA image AS17-145-22157. Credit: NASA

When humans return to the moon, they will have a formidable challenge lurking: moondust. Talc-like lunar regolith is considered the biggest operational problem faced by lunar colonists. Within days of exposure to dust, the Apollo spacesuits suffered from darkened visors, clogged mechanisms, and eroded suit layers. Therefore, an ESA team is looking for novel material options to serve as the basis for future spacesuits or to protect rovers or fixed infrastructure.

“The idea emerged that, as ESA returns to the Moon, we should study how to take advantage of the many innovations in the field of materials since the Apollo spacesuits were designed more than half a century ago,” says the engineer from ESA Malgorzata Holynska materials and processes.

“So while we are not developing a new spacesuit at this time, we are looking into the selection of candidate materials such a suit could use, as well as protective covers for rovers or fixed machinery and infrastructure, and running some state-of-the-art testing for testing. see how they cope with simulated lunar conditions, particularly lunar dust. “

dust moon

As Apollo 12 commander Pete Conrad noted: “I think probably one of the most aggravating and restrictive facets of exploring the lunar surface is dust and its adherence to everything, regardless of the type of material, be it skin, suit material, metal, no “. it matters what it is and its restrictive, friction-like action on everything that happens. “

That turned out to include spacesuits: “The integrity of the suits held up well, but I have no doubt that with a couple more EVAs, something could have stopped. In the area where the moon boots fitted the suits, we used the outer garment and were beginning to wear through the Mylar. “

More recently, China’s Yutu-1 rover is believed to have been immobilized during its second day on the moon by moondust clogging its moving parts.

A close-up of Apollo 12 astronaut Pete Conrad’s dust-covered glove. Credit: NASA

Violent origins

Lunar dust is present throughout the moon, created by the constant bombardment of micrometeorites that breaks the rocky surface into fine particles. Unlike ground dust, it has never been eroded by water or wind, so even microscopic particles still maintain sharp edges. And the unfiltered energy from the lunar sun can impart a strong static cling to the dust.

“Depending on its area of origin, the dust can have very different chemical and abrasive characteristics, and its precise properties depend on the selected landing site, which is another factor of concern,” notes ESA structural engineer Shumit Das.

“One of the key Apollo findings was that the abrasion effects of the lunar regolith would be the main limiting factor in returning to the moon. We want to overcome that and enable spacesuits that could be used for many more spacewalks than the few performed by The Landing. Apollo: up to 2,500 hours of surface activity is our guess. “

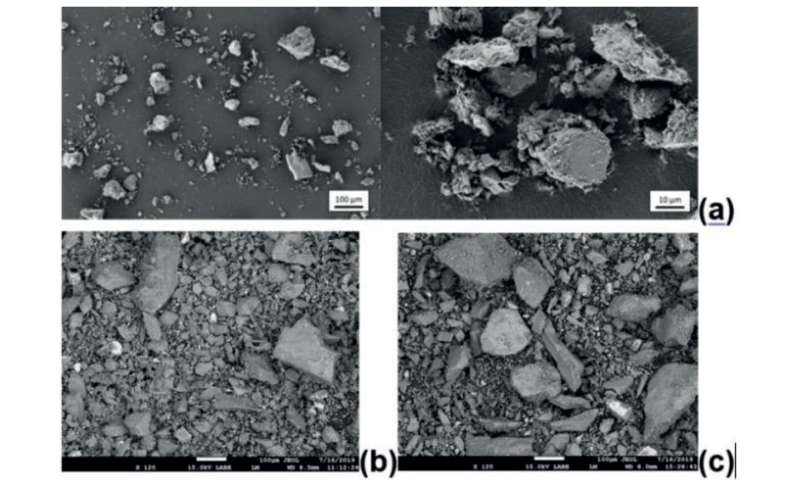

Scanning electron microscope close-ups of a simulated lunar regolith, showing (a) EAC-1A, (b) LHS-1, and (c) LMS-1. Credit: ESA

ESA is overseeing the project, in partnership with French human factors specialist Comex, the German Textile and Fiber Research Institutes and the Austrian Space Forum citizen science organization, which focuses on space suit research.

A workshop was held last year to meet with different material vendors and learn about promising options based on the latest advancements.

Tests for the success of the moon dress

“No material can really do the job,” Malgorzata adds. “Instead, the concept is to have a layered solution and define which combination of functional layers works best, in terms of physical and chemical interactions with the regolith, and how to best connect them. Then we are testing these different stacks with the criteria contributed by our colleagues from ESA’s Directorate for Human and Robotics Exploration. The challenge here is to make the evidence as robust as possible, to get credible results to guide our choice of offsets and negative selections. “

-

Bose device for fatigue tests. This test simulates the behavior of a material under great stress. The material samples are compressed and stretched, corresponding, for example, to the buckling stress in arm and knee movements. Credit: DITF

-

Turntable dual-head scorcher with lunar soil simulant. The simulant is continuously fed to the abrasive platform to account for new portions of moondust in contact with the outer layers of the suit. The tested materials are further investigated in terms of weight and microscopic image. Credit: DITF

-

Researchers at ESA’s astronaut center have identified a lunar dust substitute made up of volcanic dust from eruptions in the nearby Eifel volcanic region about 45 million years ago. This will be used in the new Luna facility and is known as EAC-1. Studies on lunar dust recreation are improving our understanding of how materials from the lunar surface could be transformed into building blocks for the next extraterrestrial base. Credit: ESA

-

An Orion spacecraft docked to the lunar outpost called Gateway. The Gateway is the next structure to be launched by the International Space Station partners. Credit: European Space Agency

The German Textile and Fiber Research Institutes are conducting most of the project testing.

“For example, an abrasion test involves placing the test material in a drum with simulated moon material bricks, to see how it lasts over time, which has been adapted from an existing textile test standard,” adds Shumit.

“Classical permeability tests are also being carried out, in which a high pressure fluid is applied to a material to see if it passes. And a test chamber is being developed for ‘thermal cycling’, exposing the material to extreme temperatures. repeated during the vacuum condition. “

The project uses a lunar simulant called EAC-1A, developed by ESA’s European Astronaut Center in Germany, processed from volcanic soil.

From spacewalks to storage

The test regime is looking at the full life cycle of any future spacesuit, including the storage time between spacewalks as well. Shumit explains: “The suits of the future would normally be stored in the Gateway in lunar orbit between the surface EVAs. We need to know that the seals of the suits, rubber or other elements will not degrade with storage time, so also Accelerated aging tests are included, including exposure to moisture and radiation. ”

Researchers develop a dust vacuum cleaner for the moon

Provided by the European Space Agency

Citation: ESA seeks dustproof materials for lunar return (2020, October 28), retrieved on October 28, 2020 from https://phys.org/news/2020-10-esa-dust-proof-materials- lunar.html

This document is subject to copyright. Apart from any fair dealing for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]