[ad_1]

A group of scientists from the National University of Hanoi has used solar energy to light the bulbs without using electricity, which is friendly to the environment.

The lighting equipment without electricity is the result of 5 years of exploration and development by the research team led by Dr. Nguyen Tran Thuat and students (Center for Nanotechnology and Energy, Center for Nano and Energy, University of Self-Science. By course, National University of Hanoi).

This is a lamp product that is used directly thanks to the sunlight focusing mechanism. This type of lamp consists of 2 parts that are the solar collector installed on the roof and the part that disperses the energy downwards, transmitting it through light tubes.

This system can be combined with the electric lighting systems in use, so there is no need for additional ceiling space for two separate lighting systems.

“Although there are light products in the world that do not use electricity, the cost of returning to Vietnam is relatively high. Therefore, the group has found the optimal solutions at the lowest prices, ”said Dr. Thuat.

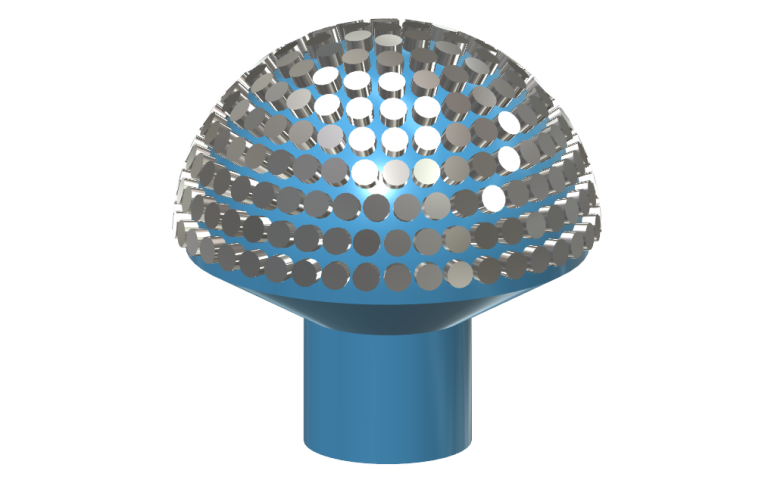

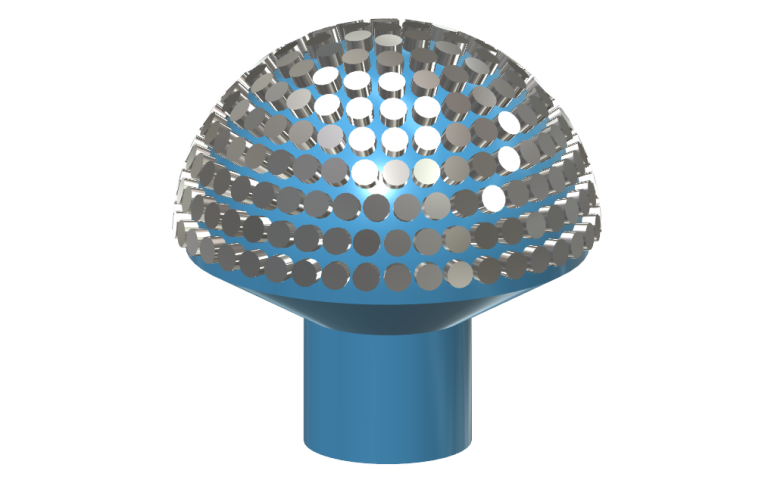

Many hexagonal and pentagonal lenses are firmly arranged and form a fixed mass.

Specifically, to create existing lighting products, the team had to test many different versions.

In the first version from 2015, the team used a large parabolic mirror to absorb sunlight on the smaller parabolic mirror. This small mirror continues to shine down the tube so that it can shine in the scattering area to illuminate the lamp.

However, the team found that using mirrors to focus light would only receive light from one direction. Meanwhile, the sunlight changes direction continuously.

This is also a disadvantage that forces the group to use motors linked to two axes so that the mirror can rotate. When the motor is used during use, it requires constant maintenance. Also, due to the need for an open area for light to enter, accidentally let in the humid environment from outside, causing damage to the device underneath.

With those limitations, the team decided to create a second version, which replaced the axially rotating parabolic mirror with many regular hexagonal and pentagonal lenses and formed a fixed mass.

Each lens will focus the light onto the optical fiber, then the fibers are formed into a beam that conducts and illuminates the natural light. This system almost improves all the limitations that version 1 still faces, such as the fixed lenses, without the need to rotate but receiving light from the sides; If it is placed on the ceiling it is still a closed device, it should not be penetrated by the humid outside environment.

With these results, the non-electric lighting equipment developed by Dr. Thuat’s research team has been patented by the National Intellectual Property Office (Ministry of Science and Technology).

Cost savings through the use of liquids

However, in the current version, the lens material the equipment is using is organic PMMA resin. According to Dr. Thuat, in the long term, if the environment is too hot, this material will age and discolor. The cost to replace or recycle is quite expensive.

Also, the available lenses are not as effective as the group expected because these are the lenses used in LEDs, which can be purchased very easily and cheaply on the market. These lenses are only optimal for light output, not optimal for light reception, so it is not feasible to take advantage of them. And manufacturing lenses according to the group’s design also faces a great challenge, because to reduce costs, it must be mass produced. The problem then will be to continue the investment to reach the market, and this source of investment is not small.

In addition to asking for more investment in the production of the previous second version, the group is also in the research process and continues to develop a third version. In this version, the group will use liquid instead. Transparent solid materials used in lenses and optical fibers.

“By using liquid materials, you get a total reflection effect on the super hydrophobic surface to transmit the light. Using a liquid in a clear container instead of a solid plastic will save money, be more convenient, easy to replace and maintain, ”said Dr. Thuat.

TS. Nguyen Tran Thuat (orange shirt) took photos with the students

However, he also said that for direct-use lamps, there will be difficulties such as being used only during the day and having to comply with design and construction standards.

However, with high applicability, this product can be effectively used in aisles and large supermarkets to reduce the electricity usage rate for daylight.

“Currently, tube houses in Vietnam receive very little natural light, so this is an inexpensive lighting solution,” said Dr. Thuat.

The next goal of the research team is to refine, transfer and develop the production scale to commercialize the product.

Thuy Nga

Postcard teachers and students create “debugging” applications for students in an instant

Many times having trouble in the learning process but slow to get feedback from the school, Viet Dung’s group intensively planned to create an app to help students answer all the questions in just a few seconds.