[ad_1]

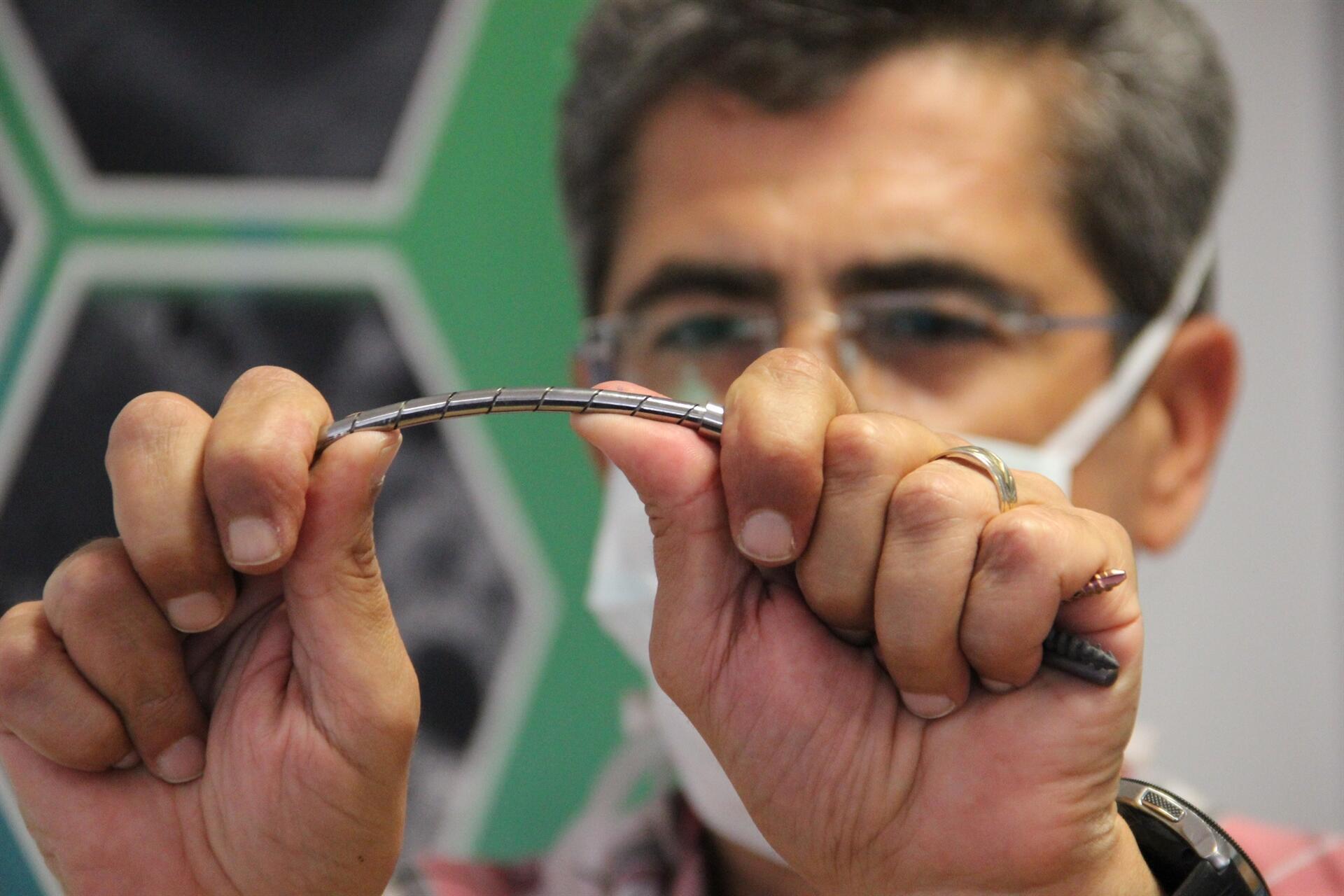

Professor of the Department of Brain and Nervous Surgery of the Faculty of Medicine of Manisa Celal Bayar University. Dr. Developed and patented by Cüneyt Temiz in 2014 for use in treating spinal disorders, Smart Spine Screws are further developed by combining science and industry, and today they are exported to many countries, mainly countries. Europeans.

The mass production of elastic rods and elastic screws, which began with university-industry cooperation, developed in technological development zones and completed clinical studies, is carried out in the Manisa Organized Industrial Zone.

class = “cf”>

ELASTIC BARS ARE IMPROVED

Drawing attention to restoring mobility in the spine with the elastic rods they developed after the smart spine screw, Manisa Celal Bayar University School of Medicine, Department of Brain and Nerve Surgery Professor. Dr. Cüneyt Temiz said: “We put two screws in the back of the transpedicular screw that we used before, but we no longer connect them with rigid rods. We connect them with elastic bars now. We can adjust its ease and flexibility. We can adjust it to vary from patient to patient. It makes a huge difference from person to person in surgery and medicine. Now we are in the stage of designing a specific implant device for each patient with the measurements that we have made beforehand. This is one of the most important things a rubber band does. Specific implant for the patient. In spinal surgery, there is a surgical method we call transpedicular screw rod stabilization that is used all over the world. This method is actually one of the methods that form the basis of spine surgery. We have seen some problems derived from the devices that we use in this surgical method. This is also due to many years of experience. The most important of these problems is that after placing the screws, we use rigid rods on the rods that connect the two screws from the rear, that is, on the rods. These rods ensure that the diseased area is fixed to heal, but we lose the movement of that segment of the spine. This causes two important events. First, there is a serious decrease in the quality of life and comfort of life of the patient. Second, because we fix that area, this time the movement is too much in the upper area of the spine, the load is concentrated and the deterioration in that area accelerates. In other words, patients have to be operated on again after a while. The elastic rod was developed primarily for this. In other words, let’s treat the segmental pathology that occurs in the spine and adjust the movement of the spine as much as we want, and the patient’s living comfort has been developed so that the patient’s living comfort is better, postoperatively, without need of reoperation, and without problems that require new surgeries in the upper segment, “he said.

class = “cf”>

“TECHNOPARKS COMBINED SCIENCE AND INDUSTRY”

class = “cf”>

Stating that the most important factors for an imported product to reach a point where it can now be exported are the laws of high-tech regions, R&D laws and circulars, Prof. Dr. Temiz said: “ Following these circulars, high-tech development zones and technoparks were established. For example, my company is located in Izmir High Technology Technopark. After that, we started partnering with industrialists with the programs and opportunities that technoparks offer. We began to meet people from all departments. This triggers a brainstorm and I pass on what I know, he passes on what he knows. He finally created a team effort. “I think technoparks were the places where industry and university or industry and science met and cooperated.”

Noting that they have 6 years of results so far, Prof. Dr. Temiz said that they had a much higher success rate in 6-year results than normal rigid bars, and a scientific publication on this will be published soon.

“THOUSAND $ 250”

Noting that 15 years ago, the column bolts were completely imported from abroad. Dr. Temiz said:

“They didn’t have them in Turkey. Less than 15 years ago we looked at the fact that not even the keel screw implanted in Turkey was generated. In the past these operations that we do, we are importing one of these screws from abroad 1,250 dollars. ¿ Why, because yapılamıyordu in Turkey. Right now it becomes a we got much more than our own patented technology and products we produce in Turkey and export abroad. Now, the patent fees for them abroad, they don’t pay the fees on the contrary, now they pay us “.

“SERIAL PRODUCTION HAS BEEN CARRIED OUT DURING THE LAST 3 YEARS”

The General Coordinator of the company, which is located in the Organized Industrial Zone of Manisa and manufactures medical devices, Mechanical Engineer Burak Tülü, “This is only 3-4 years of productive R&D, we start in technological development zones and then We produce a series of test samples and the test results are positive. It is a product that we put on the market after certification and licensing after your arrival. There are many interdisciplinary studies. From neurosurgery and orthopedic surgery, they support us in the collection of clinical data and specifying needs and creating designs. Mass production has been started for the past 3 years. At our facilities in the Manisa Organized Industrial Zone, we produce these products in volume. We export abroad and also use it in national operations. While we are trying to export a similar product in many countries in the world, we can create this product only in the global market and get good results from the clinics, which makes it easier to export this product. This allows us to increase our customer base in a short time and to facilitate the registration of our products, “he said.

EXPORTS TO THE WORLD

Noting that today they export their production to different parts of the world, Tülü said: “We export to countries like Germany, Italy, Belgium, Spain, Greece, Moldova, Ukraine in Europe and countries like Mexico, Colombia and Panama in South America. At the same time, we have clients in the Middle East and countries like Iraq and Iran. This export helps to reduce the country’s current account deficit. Until then, the import of dynamic style systems was carried out. Currently, we do this in our own country, together with our own young minds and seasoned teachers, and we make sure the currency stays in the country. We went one click further and added the relevant fairs to our current portfolio and began to export them abroad. These sales are progressing rapidly over time. In the process of R&D to mass production, we have done it with the support of 100 percent national capital. At Metrosan we prioritize this as a completely national and national capital. We are proud of this. “It is a great pride for us to produce with local and national capital and export it abroad.”