As Covid-19 infections continue to spread, the importance of keeping a clean mask with you at all times is unparalleled. But after repeated use and washing, these masks can be torn to shreds and left exposed to the virus through small frayed holes.

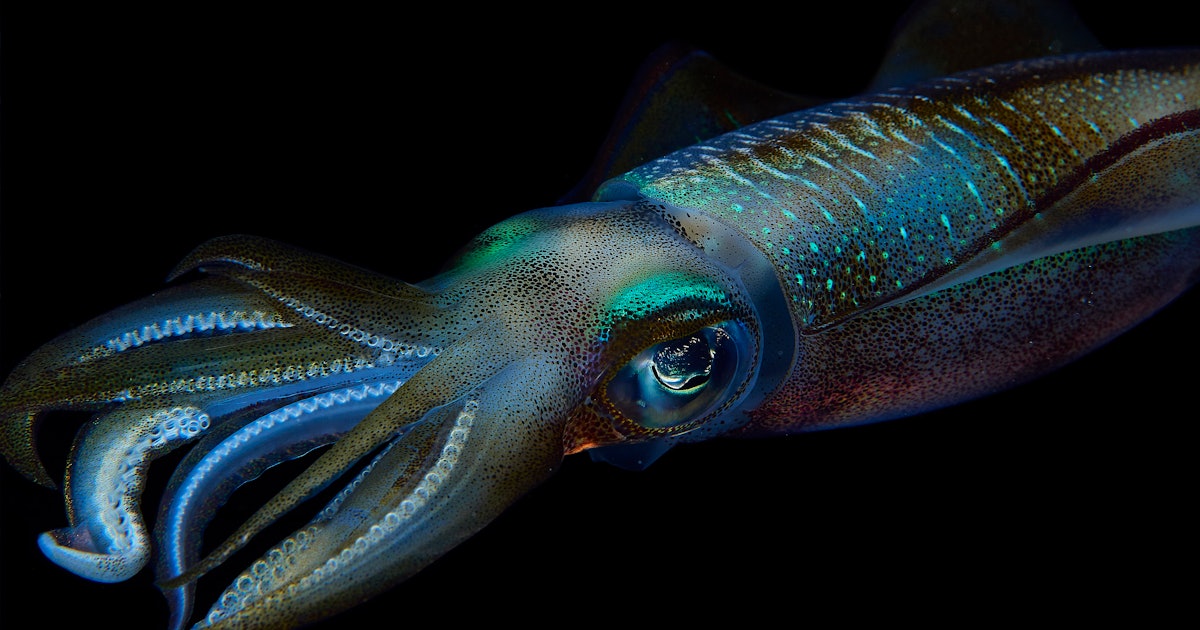

Scientists are looking to solve this problem before it becomes commonplace by synthesizing special proteins found in squid to create a self-healing material that can prolong the life of masks and fans.

In a study published Monday in the magazine. Natural materials, a team of materials scientists and engineers from Germany, Turkey, and Penn State describe how they were able to transform unique squid proteins into a soft, biodegradable material that could be used to develop soft robots and tear-resistant personal protective equipment.)

The self-healing material itself is not new in the field, but existing self-healing materials can take up to 24 hours to heal and have much lower overall resistance to damage, the researchers explain.

Its new squid-inspired material, on the other hand, can withstand tears and cuts and heal damage in just one second – while maintaining 100 percent of your previous strength.

Abdon Pena-Francelsch, first author of the study and a former PhD student at Penn State, said in a statement that transforming these natural proteins for material uses even allows them to outdo nature.

“We were able to reduce a typical cure period from 24 hours to one second so that our soft protein-based robots can now repair themselves immediately,” said Pena-Francelsch. “In nature, self-healing takes a long time. In this sense, our technology surpasses nature.”

How does it work – Mimicking a protein found in squid ring teeth, the team developed a synthetic protein that was made up of so-called “tandem repeats,” or sections of DNA that were repeated.

By controlling how these repeats occurred in the protein, the team was able to create an incredibly strong network of cross-linked proteins. Like Velcro that can be detached and reattached seamlessly, the order of the DNA repeats in these proteins makes their molecular network incredibly resistant to permanent damage.

Melik Demirel, co-author of the study and Huck chair of biomimetic materials at Penn State, says Reverse that despite its resistance, this wound healing is not autonomous.

“Don’t be self-activating,” says Demirel. Explains that to cause regeneration, the material needs water or pressure. “We anticipate that the method can be performed with light in the future.”

What was the results? To test the strength of its new material, the team subjected it to a series of tests, including being torn or cut and using it to build human-like muscles that could lift 3,000 times its own weight.

Compared to other self-healing materials that can take more than 24 hours to heal, the researchers found that their material could recover from damage in just a second, making it much more resistant in situations like hospitals where a tear A piece of PPE It could be deadly in a matter of minutes.

The team also discovered during their tests that the material could regain 100 percent of its strength after being repaired, unlike other materials that would lose some of their strength with each repair cycle.

In addition to creating tough EPP, the authors say this material could also be used to create soft, wear-resistant robots or even prosthetic limbs.

The future of PPE – In addition to developing light-based approaches to initiate self-healing of the material, the team is also working to scale the process for years to come, Demirel says. The goal is to develop products, such as prosthetics or PPE, for environments beyond the laboratory.

Part of what’s exciting about this possibility is the opportunity for green, biodegradable technology that would allow the use of this material, Demirel explains. Unlike polymer-based materials that are difficult to degrade, this biomimetic material can quickly dissolve in a simple acid like vinegar.

“From an environmental perspective, squid proteins not only provide new performance but also provide circularity,” says Demirel. “Future masks or fans can be green and have high performance.”

Summary: Self-healing materials are indispensable for soft actuators and robots operating in dynamic, real-world environments, as these machines are vulnerable to mechanical damage. However, current self-healing materials have deficiencies that limit their practical application, such as low cure resistance (below one megapascal) and long cure times (hours). Here, we introduce high-strength synthetic proteins that heal mechanical damage to micro and macroscale in one second by local heating. These materials are systematically optimized to improve their hydrogen-bound nanostructure and network morphology, with programmable curing properties (resistance from 2 to 23 MPa after 1 s of curing) that are several orders of magnitude higher than other materials soft natural and synthetic. Such a healing performance creates new opportunities for the design of bioinspired materials and addresses the current limitations in self-healing materials for soft robotics and personal protective equipment.