The world’s largest nuclear fusion project began its five-year assembly phase on Tuesday in southern France, with the first ultra-hot plasma expected to be generated in late 2025.

The € 20 billion (£ 18.2 billion) Iter project will replicate the reactions that feed the sun and is intended to demonstrate that fusion power can be generated on a commercial scale. Nuclear fusion promises clean and unlimited energy, but despite 60 years of research, it still has to overcome the technical challenges of harnessing such extreme amounts of energy.

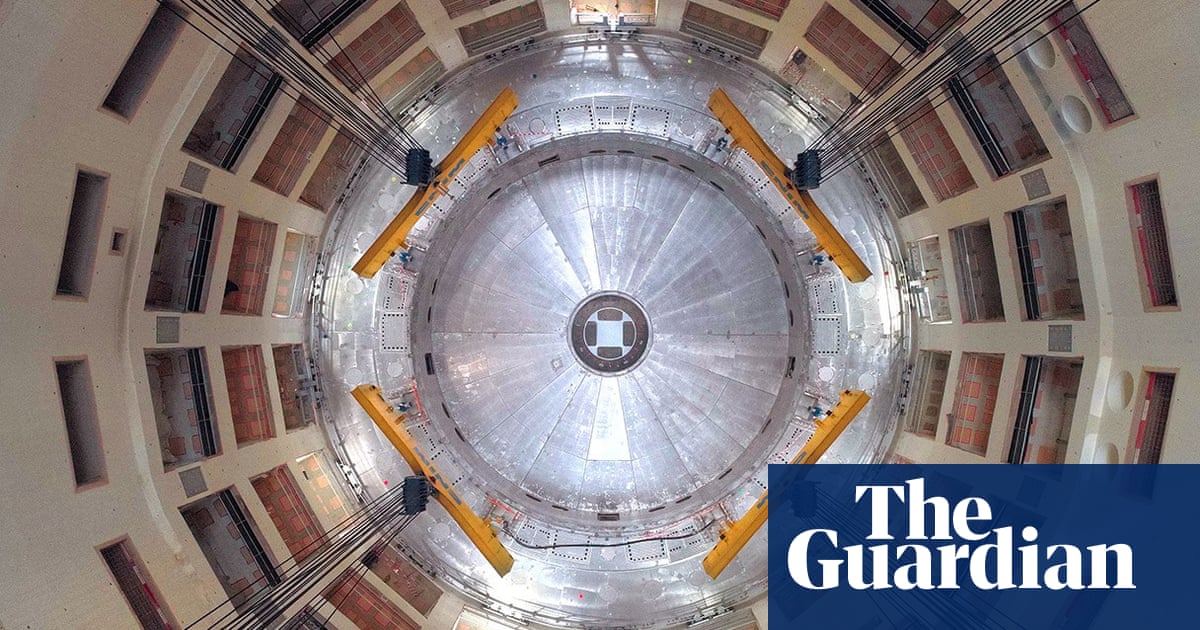

Millions of components will be used to assemble the giant reactor, which will weigh 23,000 tons and the project is the most complex engineering effort in history. Nearly 3,000 tons of superconducting magnets, some heavier than a jumbo jet, will be connected by 200 km of superconducting cables, all kept at -269C by the world’s largest cryogenic plant.

French President Emmanuel Macron launched the assembly phase, along with leading figures from members of Iter, the EU, the UK, China, India, Japan, Korea, Russia, and the United States. Shinzo Abe, the Japanese Prime Minister, said: “I believe that disruptive innovation will play a key role in addressing global problems, including climate change and the realization of a sustainable carbon-free society.”

“Allowing the exclusive use of clean energy will be a miracle for our planet,” said Bernard Bigot, CEO of Iter. He said the merger, along with renewable energy, would allow transportation, buildings, and industry to run on electricity.

But Bigot said: “Building the machine piece by piece will be like putting together a three-dimensional puzzle on an intricate timeline. [and] with the precision of a Swiss watch. “The Iter project was conceived in 1985 but has been delayed.

Nuclear fusion releases large amounts of energy when heavy hydrogen atoms fuse, but this requires a temperature of 150m C, 10 times hotter than the core of the sun. Hydrogen fuel is derived from seawater and only a few grams are needed, but huge magnets are needed to hold the plasma in the donut-shaped vacuum chamber known as tokamak.

Like conventional nuclear fission reactors, the process itself does not produce climate warming carbon dioxide, but fusion reactors cannot melt and produce far less radioactive waste.

The Iter project will be the first to achieve a “combustion” or self-heating plasma and it is expected to generate 10 times more heat than is applied, much more than any previous attempt. It will also use a significant amount of electrical power when running to power magnets and scientific instruments, but it is intended to be a large-scale proof of concept of fusion, not a design for a future commercial reactor.

Among the components that are assembled is the 30 meter diameter cryostat, manufactured by India, that surrounds the reactor and maintains it at the extremely low temperature required. One of the electromagnets, called the center solenoid and built by the US, will have the magnetic power to lift an aircraft carrier.

There are numerous private sector companies seeking nuclear fusion through much smaller devices, including the UK-based Tokamak Energy, which has raised £ 117 million in investment. Its executive vice president, David Kingham, said: “We welcome the progress at Iter that we see as a great scientific project and a great endorsement of tokamak devices.”

“But we are convinced that faster progress is possible, driven by the need for more carbon-free energy and enabled by private investment, modular designs, new materials and advanced technologies,” he said. Iter’s engineers said their giant project is the size that proven technologies can offer.

Other nuclear fusion companies include Tri Alpha Energy, which takes advantage of particle accelerator technology and is working with Google, General Fusion, which uses a molten lead-lithium vortex to hold the plasma, and is backed by Jeff Bezos of Amazon and First. Light Fusion.

.