The history of today’s stainless steel industry can be traced back to the early 19th century, when scientists found that iron-chromium alloys were resistant to corrosion by certain acids. New research, however, suggests that a similar alloy was being developed, much earlier – even a thousand years ago.

Archaeologists have discovered that what they believe is evidence of low-chromium crucible steel in the 11th century, which is now a fan in Iran, long and far from the European Industrial Revolution. The metal was used to make armor and weapons, including swords and cutters.

Stainless steel is also known as chromium steel – it contains chromium in the alloy that prevents rust – and while previous metal alloys have no definite match, it shows evidence that chromium in alloys is mixed with pig-iron. Crucible steel.

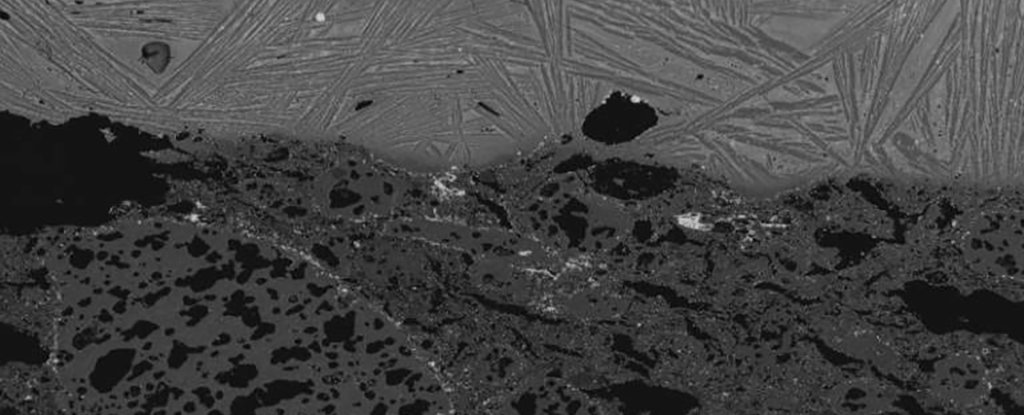

Crucible Slag (Raheel Alipore / UCL)

Crucible Slag (Raheel Alipore / UCL)

“This research not only provides the earliest known evidence for the production of chromium steel in the early 11th century CE, but also provides a chemical tracer that can help restore the identity of crucible steel archeology to its origins in museums or archeological collections.” In tradition, “said Raheel Alipore, an archaeologist at University College London.

The researchers explained in their paper “The deliberate production of low-chromium steel” that we have seen so early, meaning that stainless steel has a much longer and more varied history than experts know.

Fan is just a small village today, numerous ancient manuscripts point to it as an important hub for steel making in the Persian era, and indeed it is the only known place in the region where crucible steel was made at that time.

One of these manuscripts led researchers to their new discovery; It mentions a mysterious compound called rusakhataj (translated as “burnt”), which the team suggests was actually chromite sand.

“The process of identification can be quite long and complicated and this is for many reasons,” says Marcos Martin-Torres, an archaeologist at Cambridge University.

“First, the language and terms used to record technical processes or content may no longer be used, or their meaning and attribution may differ from those used in modern science. Furthermore, writing is limited to more social classes than the individual. Was. Who actually advanced the craft, which could lead to errors or omissions in the text. “

Through radiocarbon dating and scanning electron microscopy analysis, the team was able to identify small amounts of chromite in waste coal left over from metal formation in the 10th to 12th centuries.

This will make the tools and weapons produced by the extra chromium alloy harder and stronger. Metal workers of the day also put in phosphorus, which would have made the finished alloy easier to blend, but more brittle – which is why weapons made from the material quickly lose their value in the open market.

Persian crucible steel tools and weapons are being exhibited in museums around the world, and we now have a new interesting understanding of how they were put together – through a process that will be taken back and improved in the 1800s.

“The identity of chromium as an essential component of fan crucible steel has not yet been found in other well-known crucible steel industries,” Alipore told Gizmodo.

“That’s very important, because now we can find this element in crucible steel items and back to their production center or method.”

Research has been published in Journal of Archaeological Science.

.