(Left) OIST’s Energy Materials and Surface Sciences Unit works with solar cells and modules of different sizes. (Right) In this study, the scientists worked with 5 cm x 5 cm solar modules. Credit: OIST

Solar modules made from perovskite material gain power to transform the solar technology industry.

Researchers at the Okinawa Institute of Science and Technology Graduate University (OIST) have created next-generation solar modules with high efficiency and good stability. Manufactured from a type of material called perovskites, these solar modules can maintain high performance for over 2000 hours. Their findings, reported today (July 20, 2020) in a leading magazine, Natural energyMarketing prospects have improved.

Perovskites have the potential to revolutionize the solar technology industry. Flexible and lightweight, they promise more versatility than the heavy and rigid silicon-based cells that currently dominate the market. But scientists must overcome some major hurdles before perovskites can be commercialized.

“There are three conditions that perovskites must meet: they must be cheap to produce, highly efficient and have a long service life,” said Professor Yabing Qi, head of the OIST Unit for Energy Materials and Surface Sciences, who led This studio.

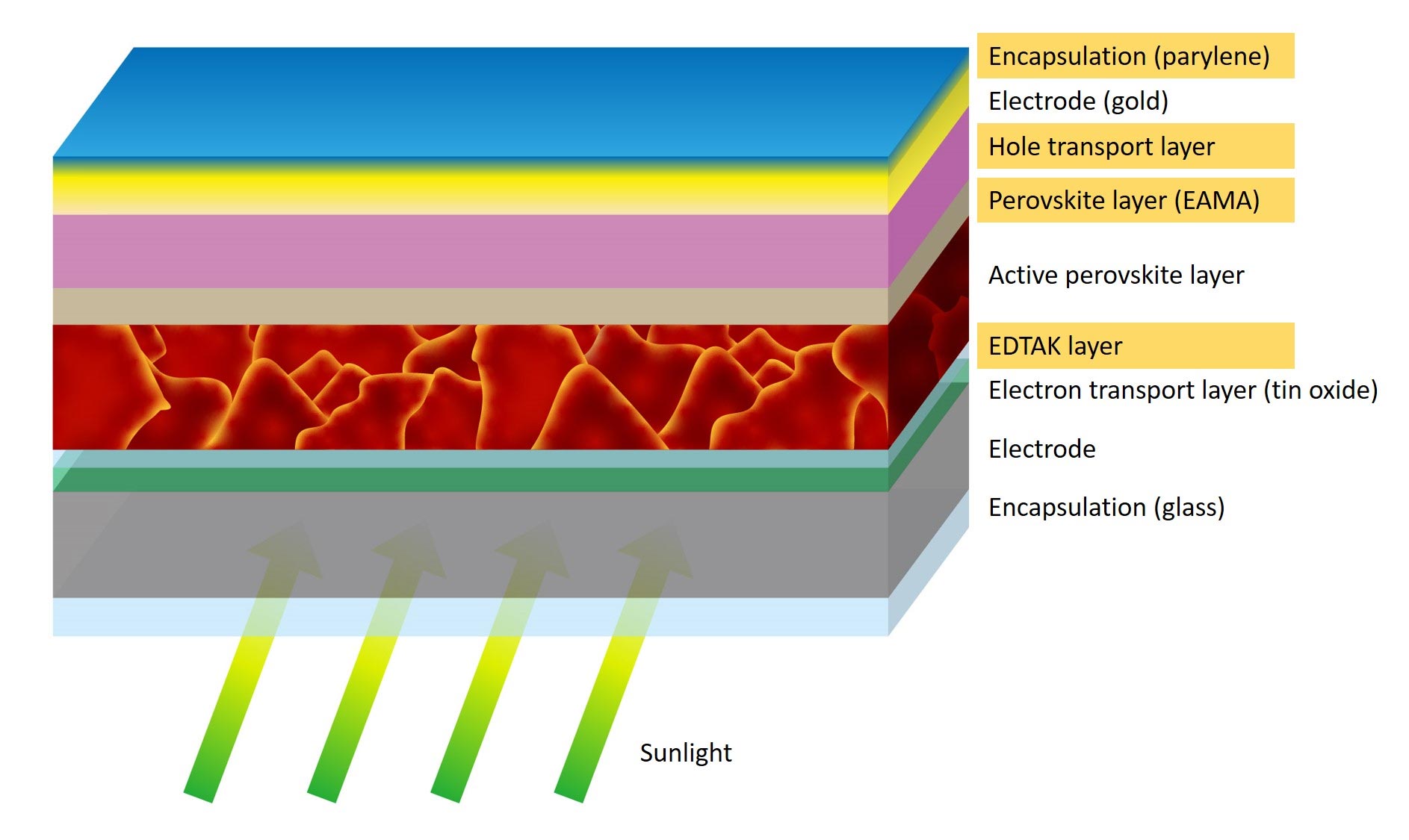

Perovskite solar cells and modules consist of many layers, each of which has a specific function. Scientists added or modified layers highlighted in orange. Credit: OIST

The cost of making perovskite solar cells is low, since cheap raw materials require little energy to process. And in just over a decade, scientists have made great strides to improve the efficiency with which perovskite solar cells convert sunlight into electricity, with efficiency levels now comparable to those of silicon-based cells.

Once expanded from small solar cells to larger solar modules, however, perovskite efficiency levels plummet. This is problematic since commercial solar technology needs to stay efficient in the size of solar panels, several feet in length.

“Enlargement is very demanding; any defect in the material becomes more pronounced, so you need high-quality materials and better manufacturing techniques, “explained Dr. Luis Ono, co-author of this study.

Perovskite instability is another key issue under intense investigation. Commercial solar cells must be able to withstand years of operation, but perovskite solar cells currently degrade rapidly.

Building the layers

Professor Qi’s team, supported by the Proof of Concept Program at the OIST Center for Technological Development and Innovation, addressed these stability and efficiency issues using a new approach. Perovskite solar devices are made up of multiple layers, each with a specific function. Instead of focusing on a single layer, they looked at the overall performance of the device and how the layers interact with each other.

The active perovskite layer, which absorbs sunlight, is located in the center of the device, sandwiched between the other layers. When light photons hit the perovskite shell, negatively charged electrons harness this energy and “jump” to a higher energy level, leaving behind positively charged “holes” where the electrons used to be. These charges are deflected in opposite directions in electron transport layers and holes above and below the active layer. This creates a flow of charge, or electricity, that can leave the solar device through electrodes. The device is also encapsulated by a protective layer that reduces degradation and prevents toxic chemicals from leaking into the environment.

In the study, the scientists worked with 22.4 cm2 solar modules.

The scientists first improved the interface between the active perovskite layer and the electron transport layer, by adding a chemical called EDTAK between the two layers. They found that EDTAK prevented the tin oxide electron transport layer from reacting with the active perovskite layer, increasing the stability of the solar module.

From left to right: Prof. Yabing Qi, Dr. Zonghao Liu, Dr. Luis K. Ono, Dr. Dae-Yong Son, Dr. Sisi He and Dr. Longbin Qiu. Credit: OIST

EDTAK also improved the efficiency of the perovskite solar module in two different ways. First, the potassium in EDTAK moved into the active perovskite layer and “healed” small defects on the perovskite surface. This prevented these defects from trapping moving electrons and holes, allowing more electricity to be generated. EDTAK also increased performance by improving the conductive properties of the tin oxide electron transport layer, facilitating electron harvesting from the perovskite layer.

Scientists made similar improvements to the interface between the perovskite active layer and the hole transport layer. This time, they added a type of perovskite called EAMA between the layers, which improved the ability of the hole transport layer to receive holes.

The EAMA-treated device also showed better stability under humidity and temperature tests. This was due to how EAMA interacts with the surface of the perovskite active layer, which is a mosaic of crystal grains. In solar devices without EAMA, scientists saw that cracks formed on the surface of the active layer, which originated from the boundaries between these grains. When the scientists added EAMA, they observed that the additional perovskite material filled the boundaries of the grains and prevented moisture from entering, preventing these cracks from forming.

The team also modified the transport layer of the well, mixing a small amount of polymer called PH3T. This polymer increased moisture resistance by providing the layer with water repellent properties.

The polymer also solved a major problem that had previously hampered improvements to long-term stability. The electrode on top of the perovskite solar module is made of thin gold strips. But over time, small gold particles migrate from the electrode, through the hole’s transport layer, and into the active perovskite layer. This irreversibly impairs the performance of the device.

When the researchers incorporated PH3T, they found that the gold particles migrated to the device more slowly, significantly increasing the life of the module.

For their final improvement, the scientists added a thin layer of polymer, parylene, in addition to glass, to provide a protective layer to the solar module. With this added protection, the solar modules maintained approximately 86% of their initial performance, even after 2000 hours of constant illumination.

In collaboration with Dr. Said Kazaoui of the National Institute of Advanced Industrial Science and Technology (AIST), the OIST team tested the improved solar modules and obtained an efficiency of 16.6%, a very high efficiency for such a solar module. size. The researchers now aim to carry out these modifications on larger solar modules, leading the way towards the development of large-scale commercial solar technology in the future.

Reference: July 20, 2020, Natural energy.

DOI: 10.1038 / s41560-020-0653-2