A research team from Caltech and UCLA’s Samuel School of Engineering has demonstrated a promising way to effectively convert carbon dioxide into ethylene – an important chemical used to produce plastics, solvents, cosmetics and other globally important products.

Scientists developed a specially shaped surface nanoscale copper wire to stimulate a chemical process that reduces greenhouse gas emissions while producing ethylene – a valuable chemical simultaneously. Reaction calculation studies show that the shaped catalyst favors the production of more ethylene than hydrogen or methane. A study detailing the advance was published Nature catalysis.

“With the challenges of global climate change, we are facing the challenge of fossil fuels,” said Yu Huang, co-author of the study and professor of materials science and engineering at UCLA. “Developing materials that can effectively convert greenhouse gases into valued fuel and chemical feed stocks to reduce global warming as more and more limited fossil fuels move away from coal. This integrated experiment and theoretical analysis presents a sustainable path to carbon dioxide upcycling and utility. “

Currently, the global annual production of ethylene is 158 million tons. Most of it is converted into polyethylene, which is used in plastic packaging. Ethylene is processed from hydrocarbons like natural gas.

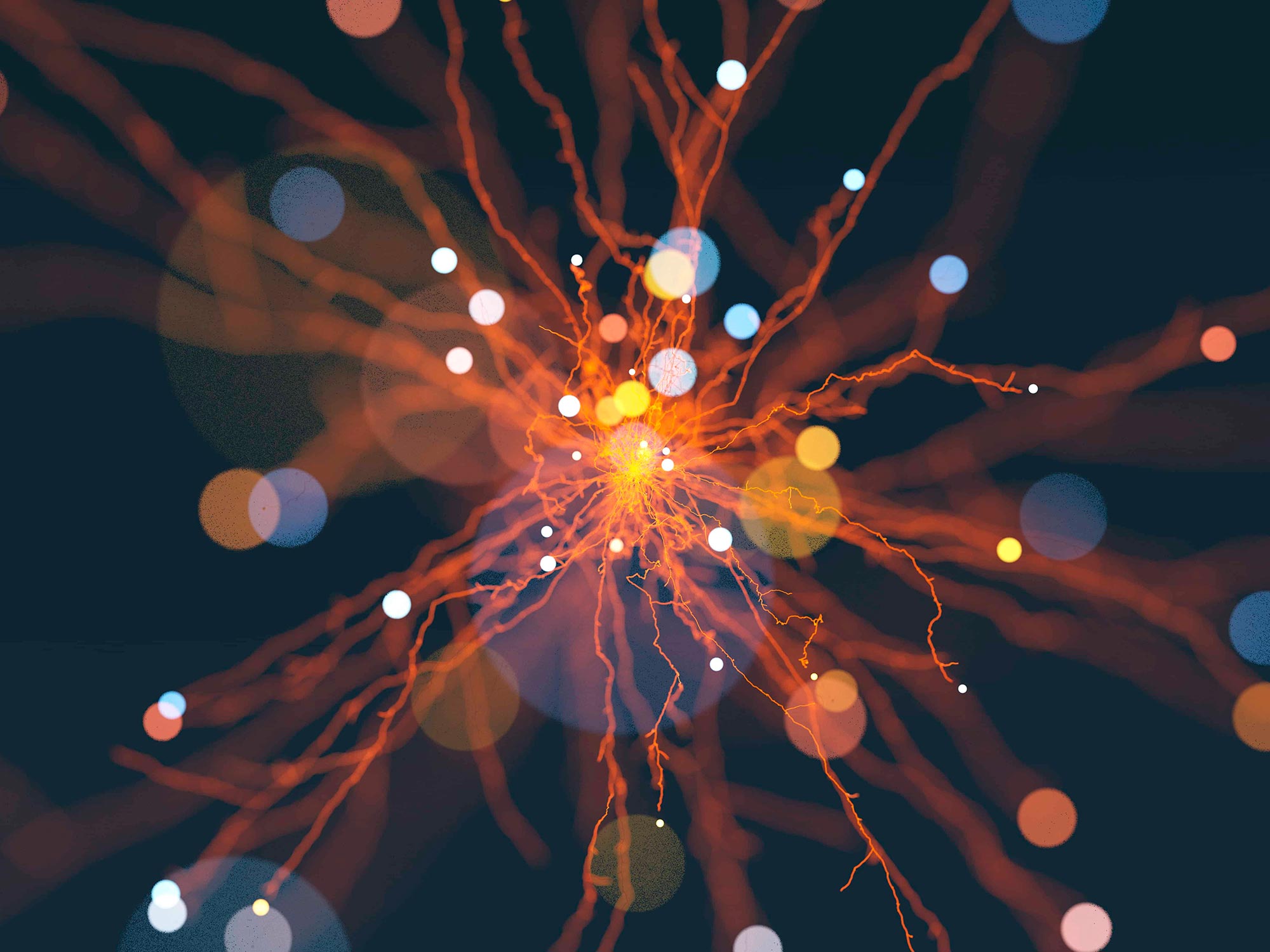

An example of an Electrog Cat talisman system that synthesized a simple nanowire and then activated it by applying a voltage to obtain a highly selective rough stepped surface to reduce CO2 in ethylene. Credit: Yu Huang and William A. Goddard III

“The idea of using copper to generate this reaction has been around for a long time, but since it is fast enough for industrial production, the key is to accelerate the rate,” said William A., co-author of the study. Goddard III and said. Charles of Caltech and Mary Farquel Professor of Chemistry, Materials Science and Applied Physics. “This study shows a solid path to that mark, with the potential to transform ethylene production into a greenery industry using CO.2 It will end up in the atmosphere. ”

Using copper to initiate carbon dioxide (CO2) Reduction in ethylene reaction (c2H.4) Has suffered two strikes against him. First, the initial chemical reaction also produced hydrogen and methane – both undesirable in industrial production. Second, previous efforts that resulted in the production of ethylene did not last long, as the conversion efficiency ceased as the system continued.

To overcome these two obstacles, the researchers focused on the design of copper nanowires with very active “steps”, like a set of ladders arranged on an excessive scale. An interesting finding of this collaborative study is that this step on the surface of the nanowires remained stable under the condition of the pattern reaction, contrary to the general belief that the symptoms of this common belief would be easier. This is the key to both durability and choice of the system in the manufacture of ethylene rather than other end products.

The team showed a carbon dioxide-to-ethylene conversion rate of more than 70%, which is more efficient than the previous design, which was found to be at least 10% lower under similar conditions. The new system lasted for 200 hours, with slight changes in conversion efficiency, a major improvement for copper-based catalysts. In addition, a broader understanding of structure-function relationships demonstrates a new approach to designing highly active and sustainable COs.2 Catalytic reduction in action.

Huang and Goddard have been frequent collaborators for many years, with Goddard’s research group focusing on theoretical causes that take into account chemical reactions, while Huang’s group creating and experimenting with new materials. The lead author on the paper is Chungsek Choi, a graduate student of Materials Science and Engineering at UCLA Semumini and a member of Huang’s Laboratory.

Reference: “Which surface of the most active and stable step for advanced electrochemical CO2 C. decrease2H.4“By Chungsek Choi, Sunho Kwon, Tao Cheng, Mingji Xi, Peter Tiu, Changsu Li, Jin Kai, Huq Mo Li, Xiaoqing Pan, Jiangfeng Duan, William A. Goddard III and Yu Huang, September 7, 2020, Nature catalysis.

DOI: 10.1038 / s41929-020-00504-x

The other authors of this study are UC Irwin; China University Hong Kong University of Science and Technology; And Korea Advanced Institute of Science and Technology.

Office of Naval Research, U.S. The research was supported by the Department of Energy, and the National Science Foundation, with additional support from the National Research Foundation of Korea, the Irwin Materials Research Institute, and ExxonMobil.