[ad_1]

One company uses its experience with tuna as a guide.

Thermo King, which revolutionized food transportation through advancements in temperature-controlled shipping before World War II, is working with pharmaceutical companies, governments and logistics companies to ensure vaccines are preserved while they travel to clinics and hospitals. . To make this happen, they have reworked the containers typically used to transport fresh tuna to Japan, which requires similar cold conditions.

“We took that product and modified it,” Francesco Incalza, president of Thermo King Europe, Middle East and Africa, told CNN Business.

Incalza said that this type of innovation would normally take years to develop.

Calling all freezers

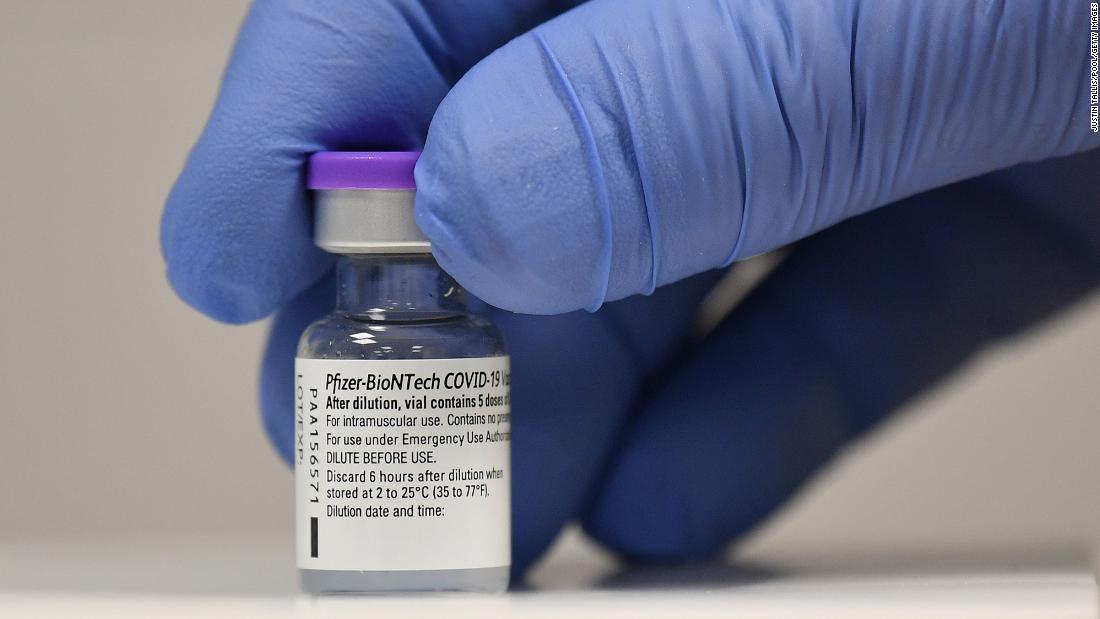

Pharmaceutical products should generally be kept at a cool temperature of 2 to 8 degrees Celsius, or approximately 36 to 46 degrees Fahrenheit, during transportation. But the Pfizer vaccine is different.

Supply chain experts They say keeping mRNA vaccines cool enough is one of the major problems in distributing vaccines around the world and ending the pandemic. But they believe it is possible, given the sophistication of the so-called “cold chain,” which for decades has driven food and medicine around the world at specific temperatures.

“It has to be planned and executed very carefully,” said Burak Kazaz, professor of supply chain management at Syracuse University. “That doesn’t mean it can’t be done, but we have to be very careful about it.”

Technology is not cheap. Imperial College London notes that much of the spending for vaccination programs comes from cold chain requirements, which can account for up to 80% of overall costs.

But the framework for moving temperature-controlled and sensitive goods around the world is there, according to Tom Jackson, author of the book “Chilled: How Refrigeration Changed the World and Might Do So Again.”

“If we get the temperatures right, we can take anything anywhere and store it for as long as we want,” Jackson said.

That’s partly thanks to Thermo King founders Frederick McKinley Jones and Joseph Numero, according to Jackson. In his book, he writes that Jones developed a more efficient refrigerated unit that could be transported on a truck after a golf buddy complained to Numero, his business partner, about a shipment of chickens spoiled during a round in 1938.

According to the US Department of Transportation, the company grew “exponentially” during World War II, when its technology was used to help preserve blood, medicine and food.

The two men were posthumously awarded the National Medal of Technology by President George HW Bush in 1991. Jones was the first black person to receive the honor.

From tuna to vaccines

A generation later, Thermo King has a role to play in managing another crisis.

In October, Trane Technologies president David Regnery told analysts that the company had developed a mobile freezer with 60 times the capacity of what was previously in the pharmaceutical market. He was referring to the modernized tuna unit.

The new product, which had been developed in consultation with drug manufacturers, was a “great opportunity for Thermo King,” he said.

Trane Technologies, which also sells heating and cooling systems for buildings and homes, will provide an update to investors on Monday. The shares, which are traded in New York, are up 35% this year.

Anticipating an increase in demand, Thermo King began ramping up production of its new units at a facility in China a few months ago, according to Incalza. He sees the initial distribution of shots later this year as part of a crucial test ahead of a mass distribution mandate in 2021.

“When spring comes, we are talking about billions and billions of doses to be distributed,” he said.

The new units could also prove useful well beyond the pandemic, Incalza said, given the rise in gene therapies and other biopharmaceuticals. Those will also require movement and storage in extremely cold temperatures.

“More and more products will have to be transported at these ultra-low temperatures, which is why a new market is opening for this type of equipment,” he said.

However, there are big challenges, including how to deliver vaccines to less developed regions that lack the same degree of refrigeration infrastructure. Incalza said that in places like this, Thermo King hopes to deploy smaller “cold cubes” that can reach -30 degrees Celsius, or -22 degrees Fahrenheit, for the Moderna vaccine and other candidates, as they would be easier to transfer. distances.

While vaccine distribution will be a daunting task, Michael Berg, CEO of Envirotainer, a Swedish company that specializes in temperature-controlled air transport of pharmaceuticals, believes the cold chain industry is up to the task.

“It’s going to take a lot of planning [and] It’s going to require everyone to increase the capacity of their fleet, “Berg said.” But all this is happening now. “