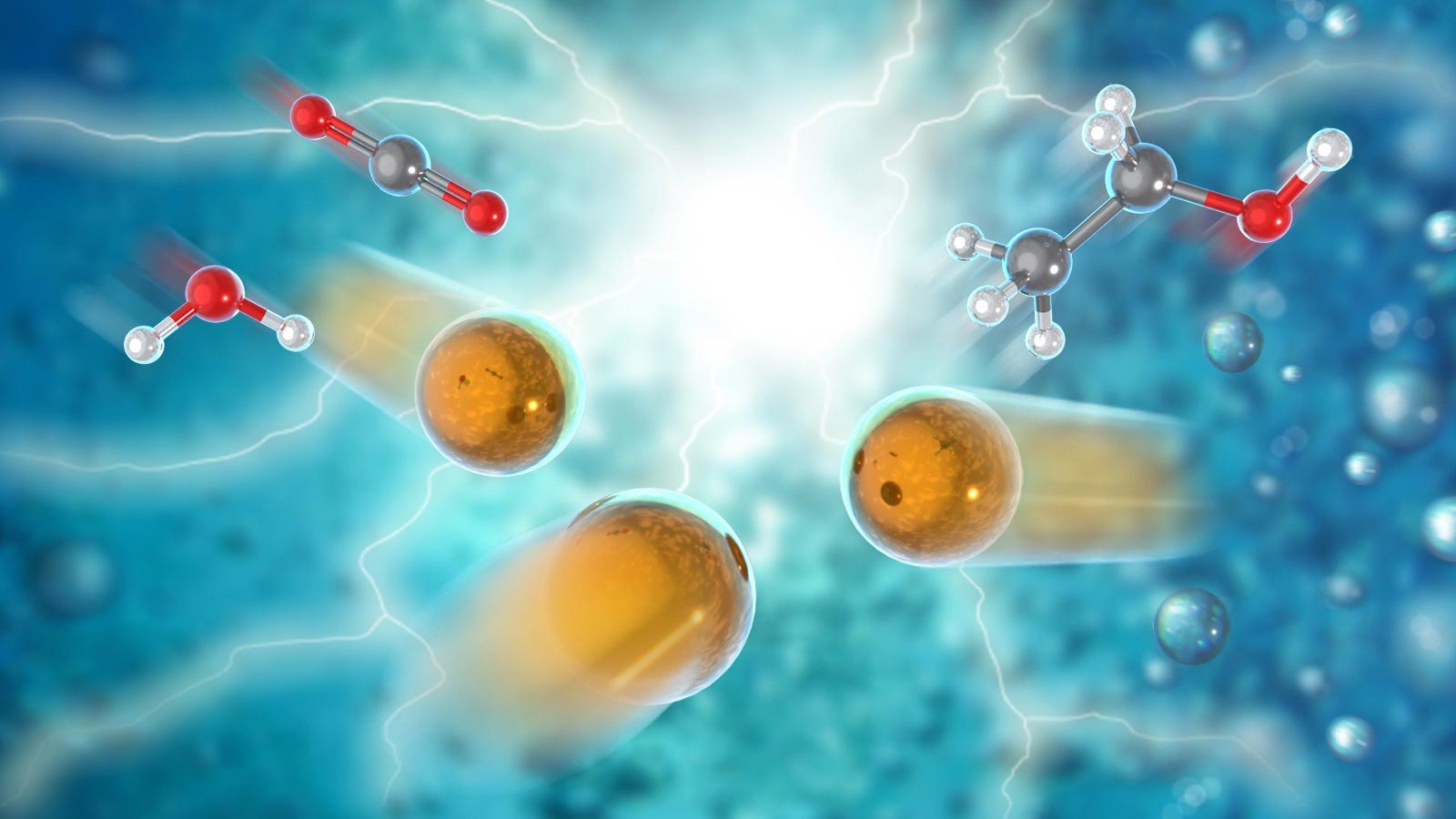

Artistic representation of electrocatalytic process for conversion of carbon dioxide and water into ethanol. Credit: Argonne National Laboratory

New electrocatalyst efficiently converts carbon dioxide into ethanol.

Catalysts accelerate chemical reactions and form the backbone of many industrial processes. For example, they are essential in transforming heavy oil into gasoline as a jet fuel. Today, catalysts are involved in more than 80 percent of all products produced.

A research team, led by the US Department of Energy’s (DOE) Argonne National Laboratory in collaboration with Northern Illinois University, has discovered a new electrocatalyst that converts carbon dioxide (CO)2) and water in ethanol with very high energy efficiency, high selectivity for the desired end product and low cost. Ethanol is a particularly desirable brand because it is an ingredient in almost every American gasoline and is widely used as an intermediate product in the chemical, pharmaceutical and cosmetics industries.

“The process resulting from our catalyst would contribute to the circular carbon economy, which includes the reuse of carbon dioxide.” – Di-Jia Liu, Senior Chemist in Argonne’s Chemical Sciences and Engineering Division and a UChicago CASE Scientist

“The process that results from our catalyst would contribute to the circular carbon economy, which includes carbon dioxide recycling,” said Di-Jia Liu, senior chemist in Argonne’s Chemical Sciences and Engineering division and a UChicago CASE scientist at Pritzker. School of Molecular Engineering, University of Chicago. This process would do this by electrochemically converting the CO2 emitted from industrial processes, such as fossil fuel energy plants or alcohol fermentation plants, in valuable goods at reasonable cost.

The team’s catalyst consists of atomically dispersed copper supported on a carbon powder. Due to an electrochemical reaction, this catalyst breaks down CO2 and water molecules and collectively collects the broken molecules into ethanol under an external electric field. The electrocatalytic selectivity, or “Faradaic efficiency,” of the process is more than 90 percent, much higher than any other reported process. What’s more, the catalyst operates stably over extended operation at low voltage.

“With this research, we have discovered a new catalytic mechanism for converting carbon dioxide and water into ethanol,” said Tao Xu, a professor of physical chemistry and nanotechnology at Northern Illinois University. “The mechanism should also support a basis for the development of highly efficient electrocatalysts for carbon dioxide conversion to a wide variety of value-added chemicals.”

Because CO2 is a stable molecule, transforming it into another molecule is usually energy intensive and costly. According to Liu, however, “We were able to couple the electrochemical process of CO2-to ethanol conversion with our catalyst to the electric grid and take advantage of the low cost electricity available from sustainable sources such as solar and wind during off-peak hours. “Because the process runs at low temperature and pressure, it can start and stop quickly in response to the intermittent supply of renewable electricity.

The team’s research benefited from two DOE Offices of Science User Facilities at Argonne – the Advanced Photon Source (APS) and Center for Nanoscale Materials (CNM) – as well as Argonne’s Laboratory Computing Resource Center (LCRC). “Thanks to the high photon flux of the X-rays at the APS, we captured the structural changes of the catalyst during the electrochemical reaction,” said Tao Li, an assistant professor in the Department of Chemistry and Biochemistry in Northern Illinois. University and an Assistant Scientist in Argonne’s X-ray Science Division This data, together with high-resolution electron microscopy at CNM and computational models with the LCRC revealed a reversible transformation of atomic scattered copper into clusters of three copper atoms each using a low voltage The CO2-to-ethanol catalysis occurs on these small copper clusters. This finding sheds light on ways to further improve the catalyst through rational design.

“We have created several new catalysts with this approach and found that they are all very efficient at converting CO2 to other hydrocarbons, ”Liu said. “We plan to continue this research in collaboration with the industry to advance this advancing technology.”

Reference: “Highly selective electrocatalytic CO2 reduction to ethanol by metallic clusters dynamically formed from atomic dispersed copper ”by Haiping Xu, Dominic Rebollar, Haiying He, Lina Chong, Yuzi Liu, Cong Liu, Cheng-Jun Sun, Tao Li, John V. Muntean, Randall E. Winans, Di-Jia Liu and Tao Xu, July 27, 2020, Natural Energy.

DOI: 10.1038 / s41560-020-0666-x

Research support came from Argonne’s Laboratory Directed Research and Development (LDRD) fund provided by the DOE Office of Science and the DOE Office of Basic Energy Sciences. The corresponding scientific paper, “Very selective electrocatalytic CO2 reduction to ethanol by metal clusters dynamically formed from atomically dispersed copper, ”appeared in a July 2020 issue of Nature Energy. In addition to Di-Jia Liu and Tao Xu, authors include Haiping Xu, Dominic Rebollar, Haiying He, Lina Chong, Yuzi Liu, Cong Liu, Cheng-Jun Sun, Tao Li, John V. Muntean, and Randall E. Winans.

About Argonne’s Center for Nanoscale Materials

The Center for Nanoscale Materials is one of the five DOE Nanoscale Science Research Centers, national facilities for users of interdisciplinary nanoscale research supported by the DOE Office of Science. Together, the NSRCs include a suite of additional facilities that provide researchers with modern capabilities to fabricate, process, characterize and model nanoscale materials, and form the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE’s Argonne, Brookhaven, Lawrence Berkeley, Oak Ridge, Sandia and Los Alamos National Laboratories.

About the advanced photon source

The U.S. Department of Energy Office of Science’s Advanced Photon Source (APS) at Argonne National Laboratory is one of the most productive X-ray images for light source in the world. The APS delivers high-brightness X-rays to a diverse community of researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. These X-rays are ideally suited for exploring materials and biological structures; element distribution; chemical, magnetic, electronic states; and a wide range of technologically important technical systems, from batteries to syringes for injectors, all of which are the foundations of our nation’s economic, technological and physical well-being. Each year, more than 5,000 researchers use the APS to produce more than 2,000 publications, which detail influential discoveries, and solve more vital biological protein structures than users of any other X-ray research facility. APS scientists and engineers innovate technology that lies at the heart of advances in accelerator and light source operations. This includes the input devices that produce X-ray images with extreme brightness, rated by researchers, lenses that focus the X-rays up to a few nanometers, instrumentation that maximizes the way the X-rays interact with investigated examples, and software which collects and manages the massive amount of data resulting from discovery research at the APS.

This research used sources from the Advanced Photon Source, a US DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.