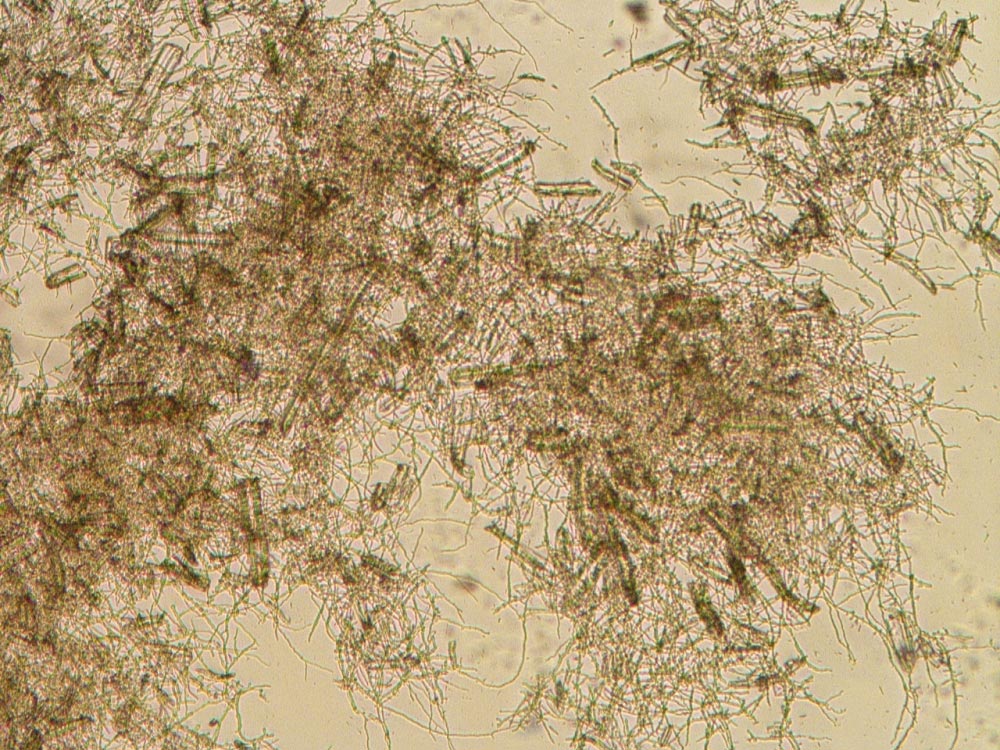

Trichoderma reesei fungus RUT-C30 strain, which was created to produce high-yielding enzymes. Credit: LNBR-CNPEM

Brazilian researchers used genetic engineering to develop a low-cost platform for the production of enzymes that break down sugar residues and bagasse for conversion into biofuels. The new molecules have many potential industrial applications.

Researchers from the Brazilian Center for Energy and Materials Research (CNPEM) have genetically engineered a fungus to produce a cocktail of enzymes that ferment the carbohydrates in biomass, such as sugar residues (tops and leaves) and bagasse, into fermentable sugars for industrial use. efficient conversion into biofuels.

The development of cheap enzyme cocktails is one of the major challenges in producing second-generation ethanol.

Second-generation biofuels are produced from various types of non-nutrient biomass, including agricultural residues, wood chips, and waste cooking oil. The process of the CNPEM research group paves the way for optimal use of sugar residues to produce biofuels.

The mold Trichoderma reesei is one of the most productive producers of plant cell wall-destroying enzymes and is widely used in the biotechnology sector. To improve their productivity as a biofactor for the enzyme cocktail in question, the researchers introduced six genetic modifications into RUT-C30, a publicly available strain of the fungus. They patented the process and reported it in an article published in the journal Biotechnology for biofuels.

“The fungus was rationally adapted to maximize the production of these enzymes of biotechnological importance. Using the CRISPR / Cas9 gene editing technique, we have modified transcription factors to regulate the expression of genes associated with the enzymes, deleted proteases that cause problems with the stability of the enzyme cocktail, and added important enzymes that ‘ t the fungus is missing in nature. As a result, we were able to produce a large amount of agro-industrial waste enzymes, a cheap and abundant feedstock in Brazil, ”Mario T. Murakami, Scientific Director of CNPEM’s Biorenewables Laboratory (LNBR), told Agência FAPESP.

Some 633 million tons of cane are processed per harvest in Brazil, producing 70 million metric tons of garbage (dry mass) every year, according to the National Food Supply Company (CONAB). This waste is underutilized for ethanol production.

Murakami claims that virtually all of the enzymes used in Brazil to decompose biomass are imported from a few foreign producers who keep the technology under trade secret protection. In this context, the imported enzyme cocktail can represent up to 50% of the production cost of a biofuel.

“Under the traditional paradigm, dozens of studies were needed to develop a competitive enzyme cocktail production platform,” he said. Moreover, the cocktails could not only be obtained by synthetic biology techniques from publicly available strains, because the producers used various methods to develop them, such as adaptive evolution, exposing the fungus to chemical reagents, and inducing genomic mutations to the most interesting phenotype “Now, however, thanks to advanced gene processing tools such as CRISPR / Cas9, we have been able to create a competitive platform in two and a half years with only a few rational modifications.”

The bioprocess developed by CNPEM researchers produced 80 grams of enzymes per liter, the highest experimental support titer ever reported for T. reesei from a low-cost sugar-based feedstock. This is more than double the concentration previously reported in the scientific literature for the fungus (37 grams per liter).

“An interesting aspect of this research is that it was not limited to the lab,” Murakami said. “We are testing the bioprocess in a semi-industrial production environment, and scaling it up for a pilot installation to assess economic viability.”

Although the platform was adapted for the production of cellulosic ethanol from sugarcane residues, he added, it can degrade other types of biomass, and advanced sugars can be used to produce other bio-renewable products, such as plastics and intermediate chemicals.

Novel enzyme class

The process was the practical result (in terms of an industrial application) of broad research conducted by LNBR to develop enzymes that can break down carbohydrates. In another study supported by FAPESP and published in Natural chemical biology, the researchers revealed seven new enzyme classes that are mainly present in fungi and bacteria.

The new enzymes belong to the family glycoside hydrolase (GH). According to Murakami, these enzymes have a significant potential for applications not only in the field of biofuels, but also in medicine, food processing and textiles, for example. The enzymes will inspire new industrial processes by utilizing the various ways in which nature derives polysaccharides (carbohydrates consisting of many simple sugars).

These enzymes remove beta-glucans, some of the most abundant polysaccharides found in the cell walls of grains, bacteria and fungi, and a large fraction of the available biomass of the world, indicating that the enzymes have potential use can be found in food preservatives and textiles. In the case of biofuels, the most important feature is their ability to deepen material rich in vegetable fibers.

“We aim to study the diversity of nature in degrading polysaccharides and how this knowledge can be applied to processes in different industries,” Murakami said. “In addition to the discovery of new enzymes, another important aspect of this research is the approach of similarity networks that we use to produce systematic and in-depth knowledge of this enzyme family. The approach enabled us to start from the beginning and reach in a relatively short time the most researched family of enzymes to date active on beta-1,3-glucans, with information available on specificity and mechanism of action. “

The most important criterion for classifying enzymes is usually phylogeny, or the evolutionary history of the molecule, while CNPEM researchers focus on functionality.

“Thanks to progress in DNA sequencing technology, we now have many known genetic sequences and a well-established capacity to study and characterize molecules and enzymes in terms of their functionality. As a result, we have been able to refine the methodology for networks of similar networks and use these for the first time to study enzymes that are active on polysaccharides, ”Murakami said.

Using the agreement network approach, the group classified seven subfamilies of the enzymes based on functionality. Characterizing at least one member of each subfamily, the researchers accessed in systematic terms the variety of molecular strategies for degrading beta-glucans contained in thousands of members of the enzyme family.

Biochemical tour de force

Phylogenetic analysis focuses on DNA regions that have been conserved over time, while classification by functionality is based on non-conserved regions that are associated with functional differentiation. “This gave us efficiency and enabled us to group more than 1,000 sequences into just seven subgroups or classes with the same function,” Murakami said.

Because the approach was novel, the researchers conducted several other studies to duplicate and validate the classification method. Of the seven groups of enzymes that can degrade polysaccharides, they received 24 completely new structures, including several substrate-enzyme complexes, which are crucial in providing information to help understand the mechanisms of action.

The study included functional and structural analyzes to understand how these enzymes work on the carbohydrates involved. “Polysaccharides come in dozens of configurations and are capable of many types of chemical bonds,” Murakami said. “We wanted to observe exactly what chemical bonds and architectures are recognized by each enzyme. For this reason, it had to be a multidisciplinary study, combining structural and functional data supported by analysis using mass spectrometry, spectroscopy, mutagenesis and diffraction experiments to elucidate the atomic structure. ”

In the “News and Views” section of the same issue of Natural chemical biology, Professor Paul Walton, Chairman of Bioinorganic Chemistry at the University of York in the UK, the glycoside hydrolase study assessed a ‘biochemical’ tour de force ‘for its innovative approach and praised its’ great insight ‘, adding that the researchers’ were able to express examples from each class and to isolate [of enzymes] to investigate whether the differences in sequences between the classes were reflected in their structures and activities. ”

References:

“Structural insight into β-1,3-glucan cleavage by a glycoside hydrolase family” by Camila R. Santos, Pedro ACR Costa, Plínio S. Vieira, Sinkler ET Gonzalez, Thamy LR Correa, Evandro A. Lima, Fernanda Mandelli, Renan AS Pirolla, Mariane N. Domingues, Lucelia Cabral, Marcele P. Martins, Rosa L. Cordeiro, Atílio T. Junior, Beatriz P. Souza, Érica T. Prates, Fabio C. Gozzo, Gabriela F. Persinoti, Munir S. Skaf and Mario T. Murakami, May 25, 2020, Natural chemical biology.

DOI: 10.1038 / s41589-020-0554-5

“Enzymes Knocks to the Job” by Paul H. Walton June 17, 2020, Natural chemical biology.

DOI: 10.1038 / s41589-020-0585-y

“Rational engineering of the Trichoderma reesei RUT-C30 strain to an industrially relevant platform for cellulase production ”by Lucas Miranda Fonseca, Lucas Salera Parreiras and Mario Tyago Murakami, 22 May 2020, Biotechnology for biofuels.

DOI: 10.1186 / s13068-020-01732-w