[ad_1]

Microsoft’s next generation gaming machine with 4K / 120Hz max output capabilityXbox Series XIt was released on November 10, 2020.Content confirmation、Real gameSometimes I definitely want to see what the content is next time! So, I tried to disassemble the Xbox Series X that I pre-ordered and got.

The new Xbox Series X | Xbox

https://www.xbox.com/ja-JP/consoles/xbox-series-x

The Xbox Series X that I received at the store I had reserved.

The main body and content of Xbox Series X are summarized in the following articles.

I took a closer look at the black square that enables 4K / 120FPS at the opening ceremony of Microsoft’s next-gen machine “Xbox Series X” –GIGAZINE

This is the main body of Xbox Series X.

To disassemble the Xbox Series XExclusive repair kit for “iFix it”I prepared a conductor.

First, remove the sticker from the back.

TorxThere was a screw, so remove it with a screwdriver.

Also, remove the plastic plate on the lower back and remove the hidden Torx screw.

Remove the back panel while pushing the claws stuck into the mesh part of the upper surface.

Pakari

The content is like that, the pieces are well packaged, and the density is quite high.

In the corner of the silent fan to cool the air on top, Microsoft’s popular shooting game ”auraThe face of the Master Chief, the main character of the series, was recorded.

Remove the screw that secures the fan …

Unplug the power cord.

I was able to pull out the silent fan.

Then I remove the rubber disc at the bottom … but it doesn’t seem to move at all even if I rotate it.

I found a claw to fix from inside the box. The rubber disk can be removed by twisting it while lifting with a flat blade screwdriver.

It looks like this when removed.

Remove all visible screws.

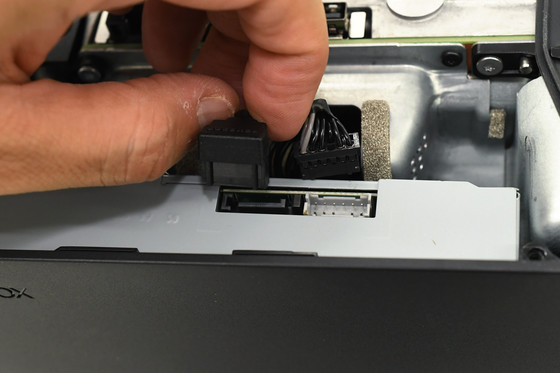

Then remove the plastic cover labeled “DISC”. There seems to be an Xbox Series X optical disc drive behind this.

Then unplug the unit.

I was able to remove the optical disc drive.

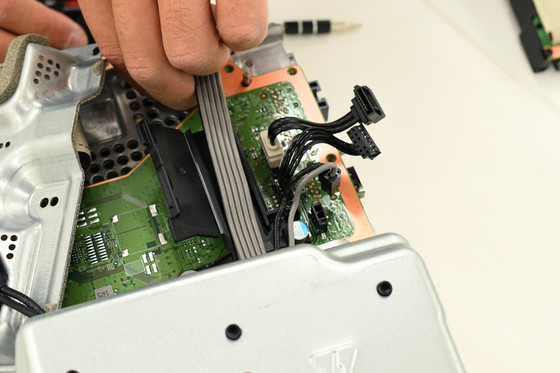

The silver cable is fixed to the case with double-sided tape, so please remove it.

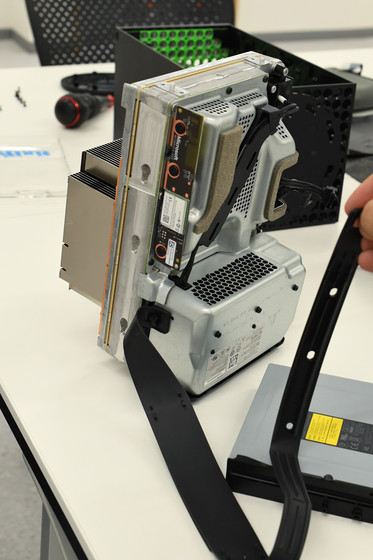

He managed to get the content out without any problems.

The ignition switch board that I disconnected when I pulled it out.

The belt that ties the contents is made of rubber and can be easily removed.

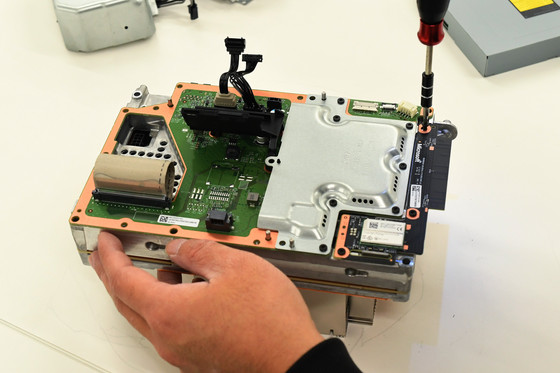

For now, remove all visible screws.

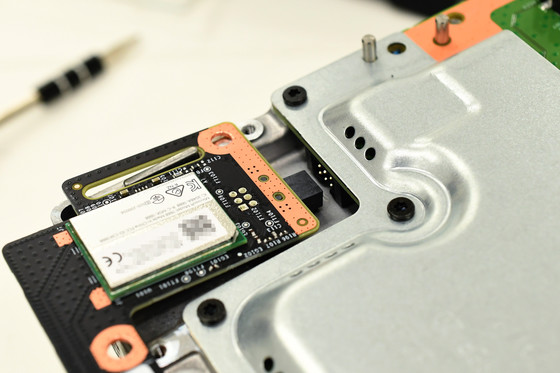

Remove the board that appears to be a Wi-Fi module attached to the side …

Remove the metal frame.

It is the power supply that rises.

The cable that runs from the power supply is fixed with plastic pieces, so remove it.

He managed to remove the power supply unit.

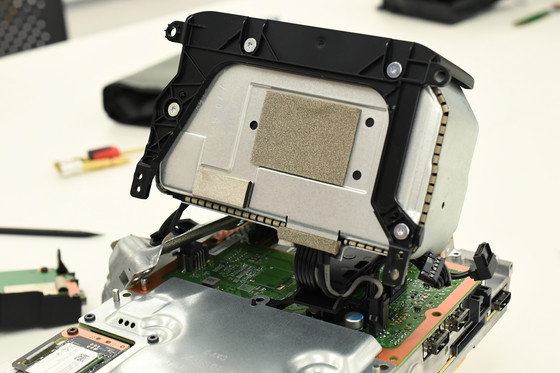

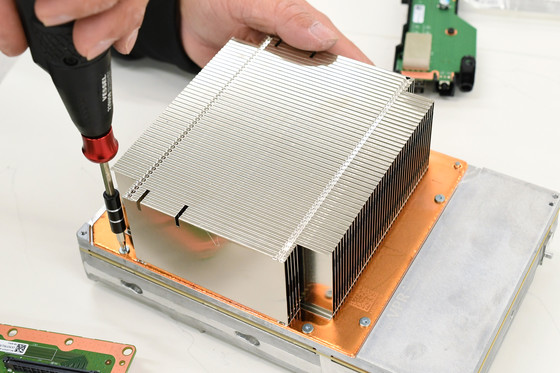

Since the motherboard and the heat sink are fixed with the die-cast frame between them, remove the screws.

Lift and gently remove the board that got stuck from the side …

Remove the metal cover.

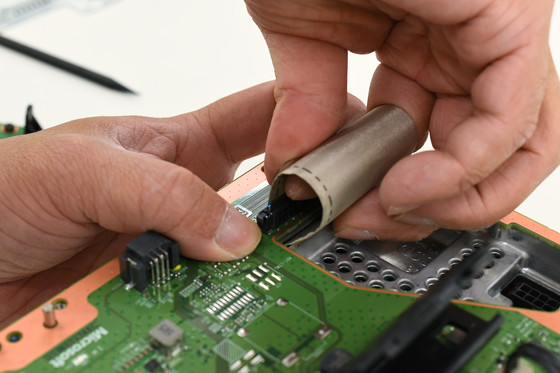

Remove the brown wire …

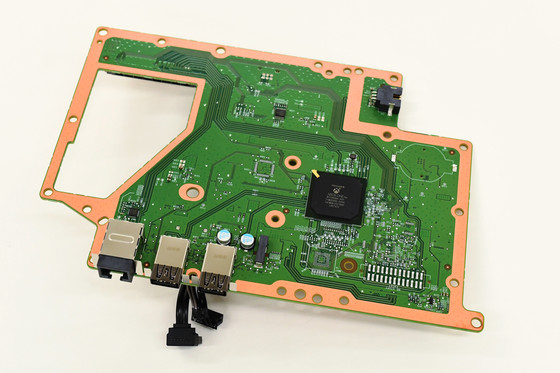

This is the removed board.

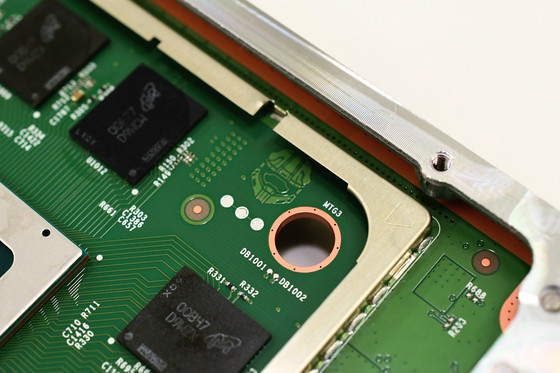

There was a chip with the Xbox One logo on it.

Also remove the screws around the heat sink.

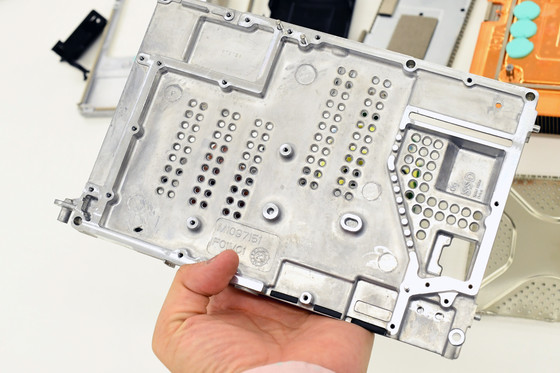

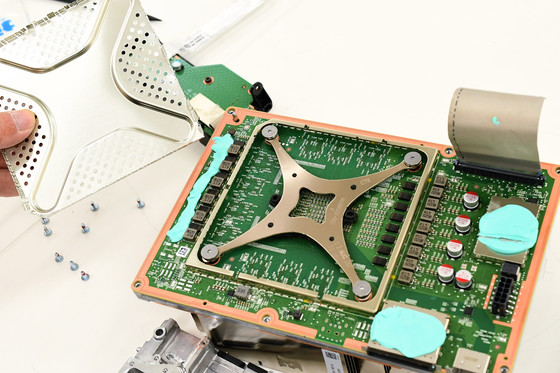

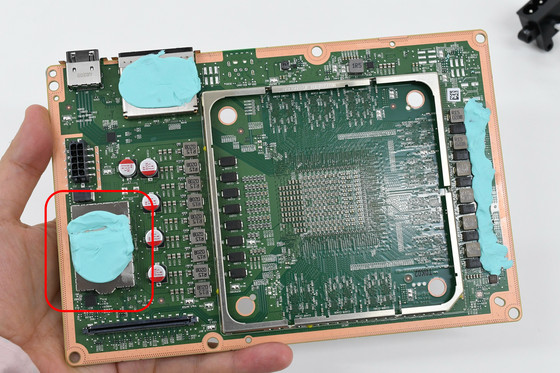

He managed to remove the die-cast frame. A perforated metal shield covers most of the board. Green clay is cool to the touch and appears to be a highly thermally conductive material like CPU grease.

The die cast frame looks like this.

Use a flat-head screwdriver to lift all of the shield claws biting into the board.

Pakari

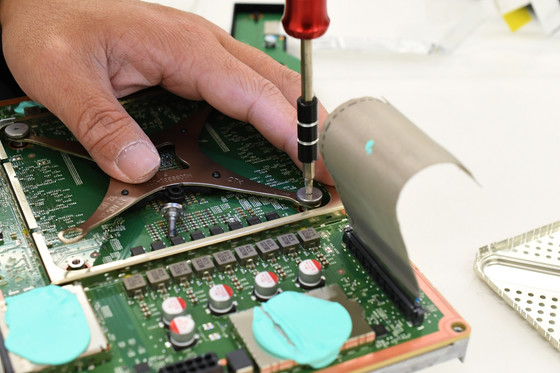

If you remove the arm holding the X-shaped shield …

I was able to remove the heat sink.

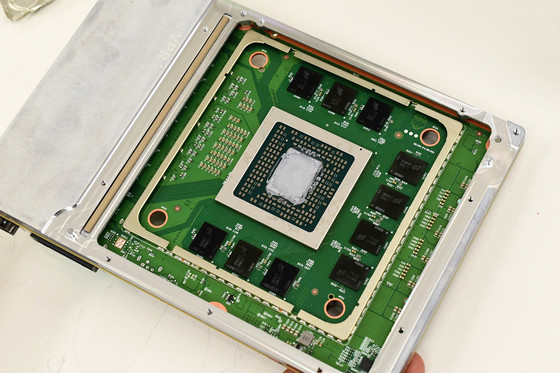

Below the heat sink is the main board, in the center is the Xbox Series X SoC and around it is the memory.

The Master Chief’s face was imprinted on the corner of the main board.

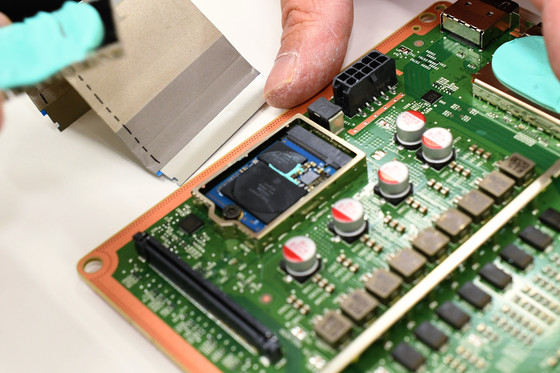

There was a part covered with a shield on the back of the main board, so when I lifted the claw with a flat-head screwdriver and removed it …

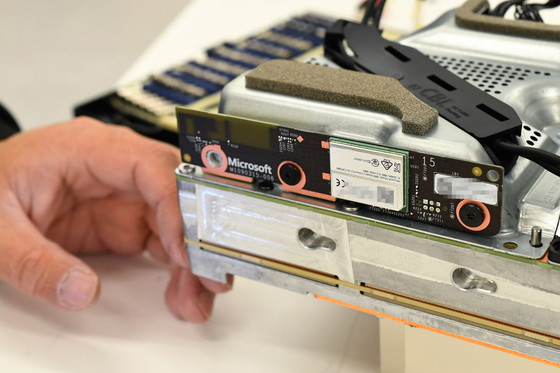

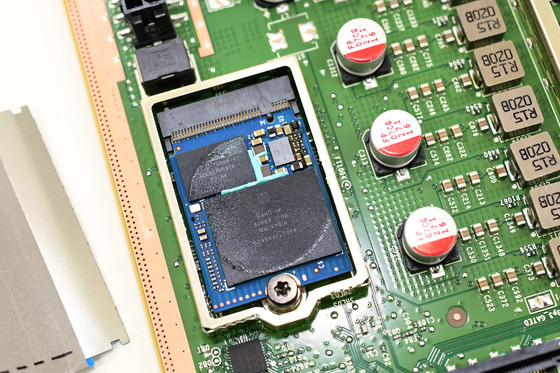

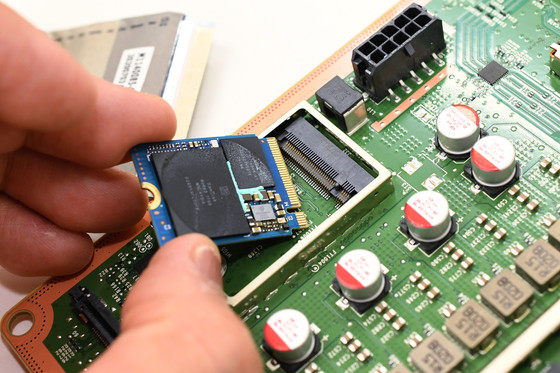

The SSD fits.

It is apparently an M.2 connection.

After removing the screw and pulling it gently, I was able to safely remove the SSD.

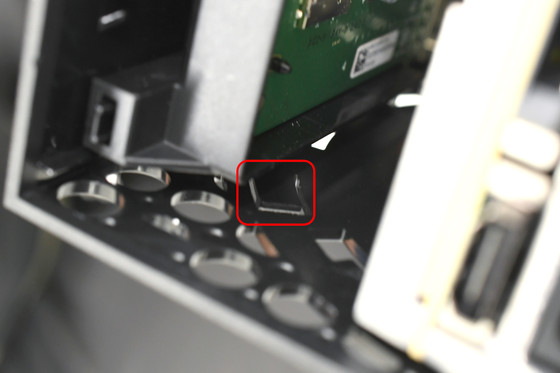

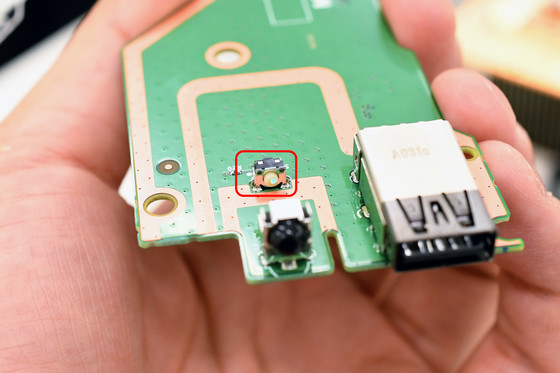

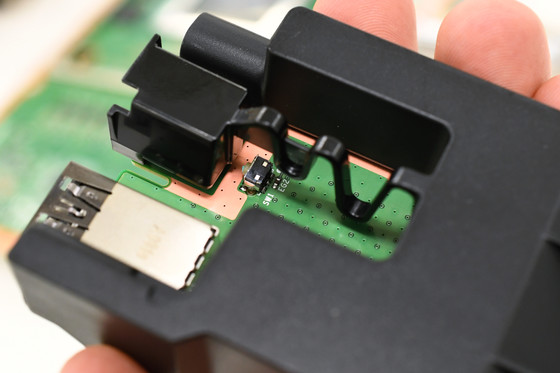

This is the USB board to connect the controller, which was attached to the side of the main board. There is a small switch next to the USB connector and a sensor in front.

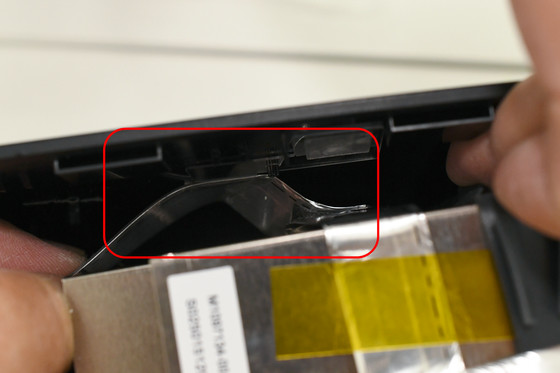

The plastic parts are attached to this plate, and while the box protects the sensor as shown below, a part of the box presses the switch with a plastic spring.

I was able to break everything like that. The disassembly work takes about 3 hours. There were parts that were firmly fixed with claws, and because they were combined in a complicated way, there were many situations where it was difficult to remove them even with tools.

This is the only screw that is used.

We’ll take a closer look at each part below, so stay tuned.

·to be continue

Copy the title and URL of this article.

[ad_2]