[ad_1]

As for the global automotive semiconductor shortage, which is causing a series of production adjustments by automakers, there is concern among analysts that the supply shortage will continue. This is because the impact of the spread of the new coronavirus infection is difficult to read and the demand forecast is difficult.

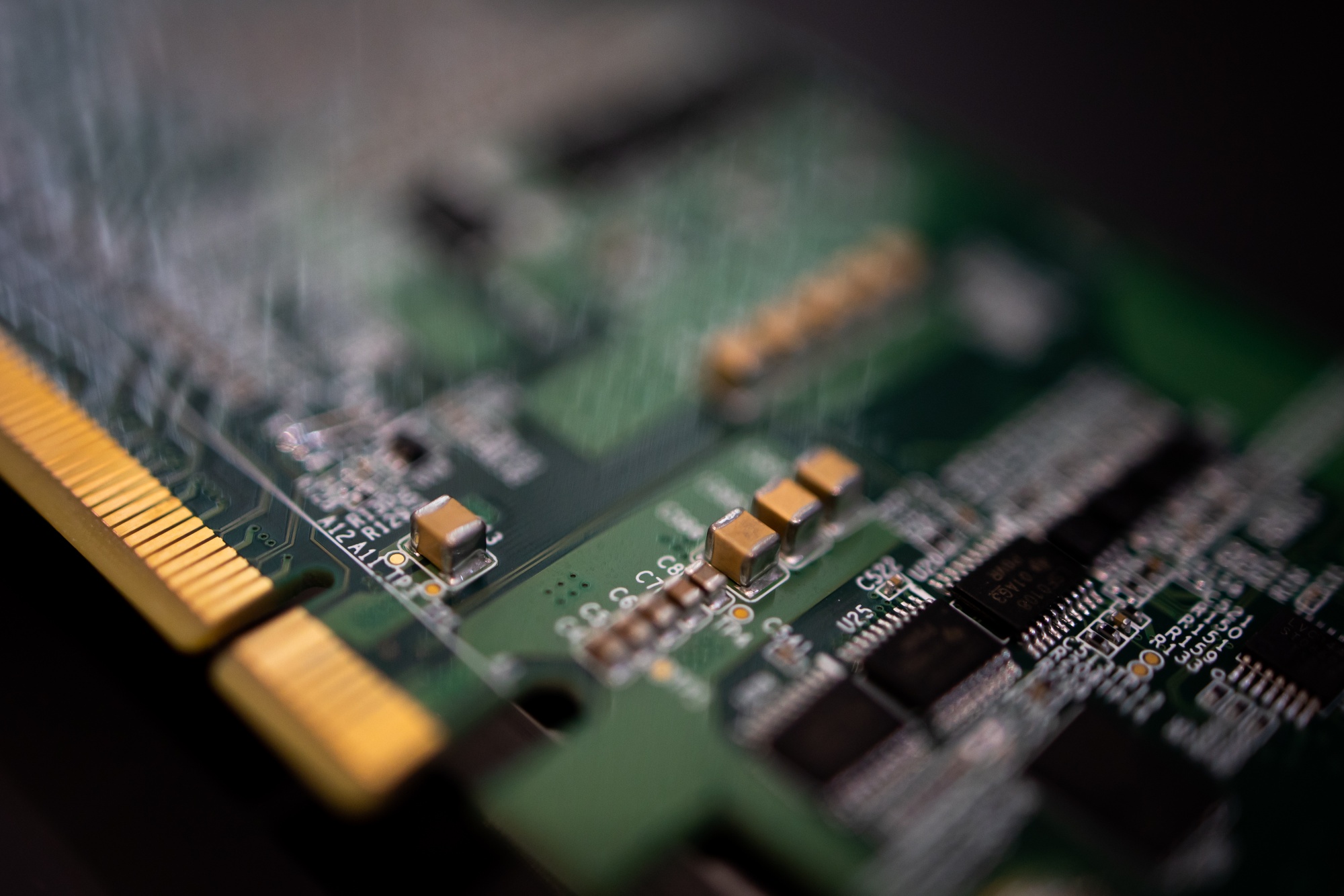

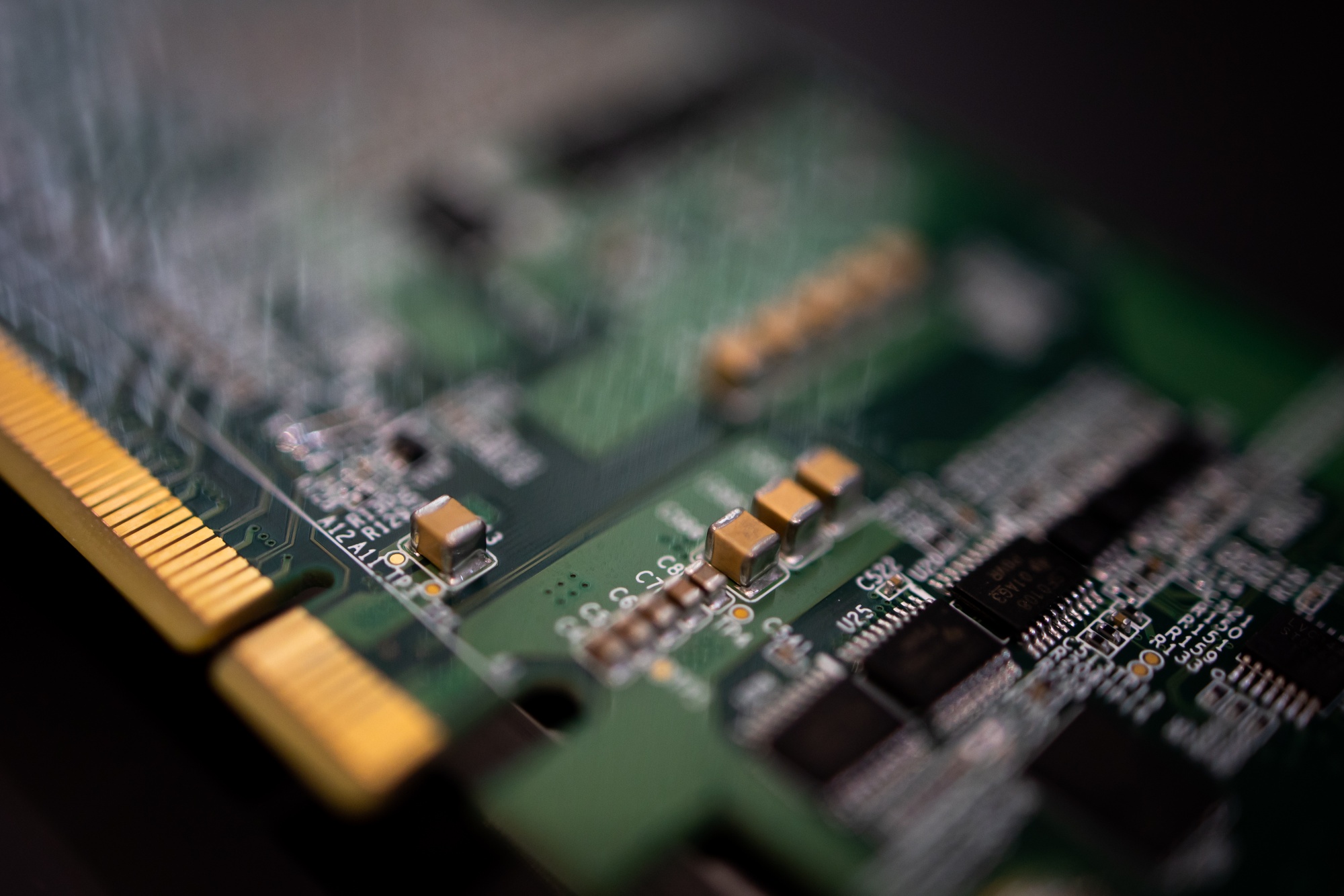

SK Telecom integrated circuit

Photographer: SeongJoon Cho / Bloomberg

Miji Izumi, a senior analyst at SBI Securities, said that due to the shortage of semiconductors in vehicles, auto companies expected a decrease in demand in the first half of 2020 and a reduction in acquisitions, and “semiconductor manufacturers prioritized supplying smartphones. ” Analyze that you are in a “no reach to car” state.

Toyota Motor Corporation, Honda and Volkswagen (VW) of Germany have decided to adjust production due to the shortage of semiconductors. Due to Corona’s influence, each company reduced production from last spring to early summer. Analysts say semiconductor makers once cut car production and supply has been unable to keep pace with the car market’s recovery, especially in China.

We handle microcomputers that control electronic components and power semiconductors that manage power supplies.Renesas Electronics is working to raise the occupancy rate at its own factory, which was lowered in April and June of last year. Kyoko Okamoto, a spokeswoman, said: “We are stepping on the accelerator of production to respond to the rapid increase in demand.”

Semiconductors for vehicles have a wide range of applications, from powertrain systems, as actuators, to safety systems, such as brakes and airbags, to power windows and air conditioners. More semiconductors are required for electric vehicles and self-driving technology, which have more electronic parts than gasoline vehicles.

The sudden increase in production is difficult

Akira Minamikawa, senior director of consulting at British research firm OMDIA, analyzed that automakers are “moving forward” in production plans for electric vehicles (EV) and hybrid vehicles (HV) as environmental awareness increases, which is also a factor in the semiconductor shortage. What to do.

Mr. Minamikawa predicts that the factory utilization rate of the world’s leading semiconductor manufacturers reached 87% in October-December last year and will exceed 90% in January-March this year, which is a guideline for shortage. It will take more than a year to expand the production capacity, so it is difficult to drastically increase the production of semiconductors in vehicles.

Masahiro Wakasugi, an analyst at Bloomberg Intelligence, said the semiconductor shortage in vehicles will be resolved in the spring. However, since demand for automobiles cannot be predicted, there is concern that inventory adjustments will occur again.

Omdia’s Mr. Minamikawa said that demand for 5G smartphones and data centers is strong around the world, and “I think there will be a significant shortage of automotive semiconductors this year.”

Taiwan Integrated Circuit Manufacturing (Wei Tetsuya, CEO of TSMC), announced on the 14th that it is cooperating with customers in the automotive industry to solve production and supply capacity issues.