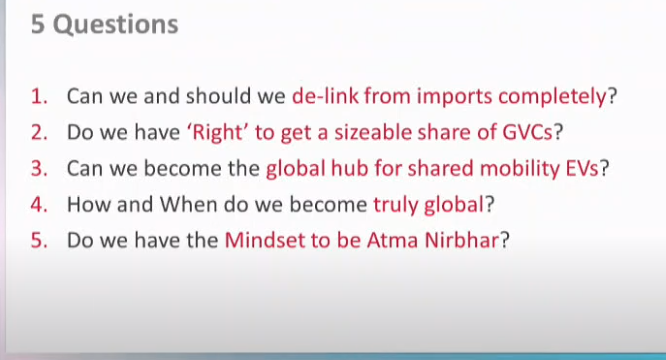

New Delhi: Pawan Goenka, Managing Director of Mahindra & Mahindra, posed five provocative and pertinent questions to the Indian auto industry that need to be addressed in order to position it globally.

The industry stalwart spoke at ACMA’s 60th annual convention, where he called the coronavirus pandemic a God-sent opportunity for Indian manufacturing and in particular for the Indian auto components industry.

The automotive industry is highly dependent on imports, especially in key electronics and technology areas related to safety emissions and electric vehicles. India’s share of the global auto components export market is about 1.3%, although India is the fifth largest auto producer.

The managing director, while answering the five rhetorical questions, paves the way for the Indian auto industry to position itself in the global market.

1. Can we and should we completely decouple from imports?

Goenka replied, “We neither can nor must. We will have to continue to import things that other countries can do better than us. And that’s okay. We don’t have to do everything ourselves. Trade is important to the national and world economy. “

However, he suggested that the industry should defer any knee-jerk reaction to call for an import ban or any such action that could have potential repercussions on the industry and retaliation by other countries.

Pointing out the top three reasons for imports which are: cost-benefit, capacity constraints in India, technology and capacity gap, he suggested that the Government of India should work together with industry stakeholders to eliminate disabilities. .

Now is the time to invest in EV technology and become a leading source of EV components and software in the shared mobility space.~

According to him, the problem is not that another country has better technological capacity. “I personally do not care about this since we cannot have the technological experience in everything. But what worries me is that there is very little technological innovation in India. What is the true R&D spending of the Indian component industry and how does it compare to Germany, Korea or Japan? “

2. Do we have the “right” to obtain a substantial stake from the GVCs?

There is a global value chain (GVC) in the export of automotive components and participation in GVC is a vast opportunity. Global export of components is worth approximately $ 1.7 trillion. In that, Germany’s contribution is 15%, China 11%, South Korea 6% and only 1.3%. “Why?” Goenka asks.

Despite the majority of multinational auto component manufacturers having a presence in India, these companies have established large-scale mother plants in various parts of the world but not in India and use these plants to source globally.

The industry needs to invest in technology, technological innovation and capacity to make India an attractive place for these mother plants of multinationals.

For that, India needs to build a narrative for exporting components as well as technology for Germany, quality for Japan, value for money for Korea, and scale and cost for China.

India’s narrative needs to be clearly articulated to push international mega-vendors like Bosch, Continental and Magna to integrate India into their global technology value chain, Goenka said.

“You have to identify where you need a technology partner and where you need to develop in-house technology with globally competitive quality, cost and scale,” he suggested.

3. Can we become the global hub for shared mobility electric vehicles?

The industry veteran stated that now is the time to invest in EV technology and become a leading source of EV components and software in the shared mobility space.

India needs to build a narrative for component export as well as technology for Germany, quality for Japan, value for money for Korea, and scale and cost for China.~

India has achieved this feat in IT software and this can be replicated in the electric vehicle component sector as well, albeit with significant investment from auto companies in technology.

“Everyone is waiting for volumes. In China, capacity was built before demand and demand followed. So OEMs need to start investing in technology to attract customers, ”Goenka said.

4. How and when do we become truly global?

To become truly global, the Indian auto industry must have a two-pronged strategy: a continued focus on technology and innovation, and explore inorganic growth and the aspiration to reach that level, Goenka said.

The top 50 global suppliers are mainly from Germany, Japan, France, the United States and China. The list includes only one supplier from India, namely Motherson Sumi. However, there are some other success stories like Bharat Forge.

5. Do we have the mentality of becoming Atma Nirbhar Bharat?

Goenka believes that the path to Atmanirbhar Bharat is on our mind first. “We have to believe in ourselves and in the vision of the Prime Minister. We need to work together as SIAM, ACMA members and Government of India to make this vision a reality, ”he said.

The government is much more serious than ever to make India a global manufacturing center. The auto components industry has the ability to be one of those manufacturing hubs.

The industry should reflect: “How can the Indian automotive components industry double its R&D spending without asking for the 200% weighted deduction?”

The bottom line

“We all have to regroup as an industry to take the Indian auto industry to greater heights. We had a dream career from 1993 to 2015. Let’s start the second wave of growth in the Indian auto industry. But remember what got us there will not necessarily get us there. We have to play the game differently. We have to redefine the game. Friends, let’s redefine the new normal that will chart the new growth path, ”concluded Goenka.

Also read: Real proof of sustainable demand from January 2021: Pawan Goenka

.