[ad_1]

A few meters from the inhabited area, under Triple Border Hill, one of the most mysterious underground facilities in the country opens, the discovery of which we made a video of six years ago. Back then, we didn’t know who and why the iron and concrete monster was built, from which a beautiful crystal cave opens, and experts only guessed.

I recently received information that Cavers later found in Section IV of the 1960 Construction and Transportation Science Bulletins. In Volume 4 an article describing exactly for what purpose and with what technical solution the tunnel and gigantic tank were built iron pressed against the rock.

Article title: Frigyes Kovácsházy – Gas tank installed on a rock

- Why were huge holes drilled at Triple Boundary Mountain?

- What did the facility look like as a subway tunnel?

- Why did the great plan become nothing?

Some people don’t have questions anymore, And there are those who read the Index.

The function was immediately revealed in the title, and why we get an answer from the first few paragraphs of the script. The increasing consumption of gas energy in the 1950s required increasing volumes of gas storage. Until then, only steel-frame gas tanks were established. Spherical or cylindrical tanks required the safe storage of high-pressure gas with a steel wall of considerable thickness, a great need for steel that was highly sought after by industry policy leaders at the time.

To save on steel material, chief engineer Frigyes Szász had an original idea:

If the gas carrier is installed in a rock such that the rock-cut cavity receives only a thin sheet of steel lining, the charge caused by the internal pressure of the gas is predominantly absorbed by the rock.

The solution is especially economical if the gas can be stored under high pressure, because then the space required, and therefore the work of extracting and lining rocks, is small. It becomes particularly advantageous if the gas reaches the transmission line at high pressure from the start. The plan was quickly implemented: but first we had to find the location of the gas storage system in Budapest.

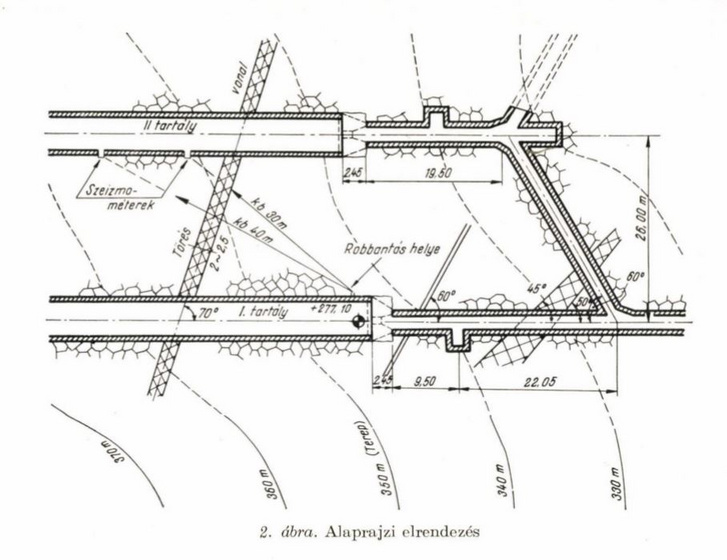

Technical drawing of the report

The choice of dr. According to the expert opinion of geologist Tibor Szalay, it fell on the Tábor-hegy dolomite rock belonging to the Hármashatár hill block. This hornstone dolomite formation is thicker than 200 meters, making it suitable for absorbing forces. In addition, it is above the karst water level, so excavation and construction work could be carried out dry, and finally it is close to the place of use (Óbuda Gas Factory).

It was built with concrete elements like a subway tunnel.

After site selection, a six-meter diameter tunnel was lined up by blasting and then rock mining, lined with a ring of 28-cm-thick, 37-pound concrete blocks. The cement mortar was pressed into the space between the ring and the rock wall to allow the concrete to fully rest.

The reservoir leading to the “subway tunnel” was also the construction transportation corridor. The two-meter-high horseshoe-shaped passage was covered with a brick wall. In this corridor, the 6 mm thick steel plates required for the construction of the tank were delivered, which were connected by arc welding. The spaces between the slab and the concrete ring were re-injected with cement mortar.

The tank from inside – like a subway tunnel (Photo: Szabó R. Zoltán)

The experimental tank with an internal volume of 416 cubic meters was first subjected to a water pressure test. The tank ran smoothly up to a limit of 22 atmospheres and no structural change or damage was observed after draining the water. After drying the tank, an air pressure test was also performed. The experiment showed that the experimental gas carrier installed in the dolomite rock well withstood the internal overpressure approaching 15 atmospheres, even within the stress limits of elastic deformations.

The test was successful: Triple Border Mountain did not fly in the air.

At the end of the description, it also turns out that a lot of creative ideas, design, sweat work pays off: Rock-installed tanks are 5-6 percent cheaper overall than outdoor-built steel tanks. The original report can be downloaded in its entirety by clicking here.

Unfortunately, the designers were finally unable to harvest the laurels because other experiments were conducted in parallel to build gas storage facilities. The essence of the winning version was that the geological formations, the underground voids from which the natural gas had previously been extracted, were reused as a huge tank, pumping the gas there.

The first facility of this type in Hungary was put into operation near Őriszentpeter in 1960, almost immediately at the end of the Tábor-hegy experiment. As there were not as many construction costs here as in the case of the tank attached to rock, it is not surprising that this technology has been extended to gas storage in Hungary. The zeriszentpeter reservoir was soon followed by several in Hajdúszoboszló, Pusztaederics, Kardoskút and Zsana. From this, even the merits of the designers and creators of the Tábor Hill installation, which have been kept secret for decades, are indisputable even today.

[ad_2]