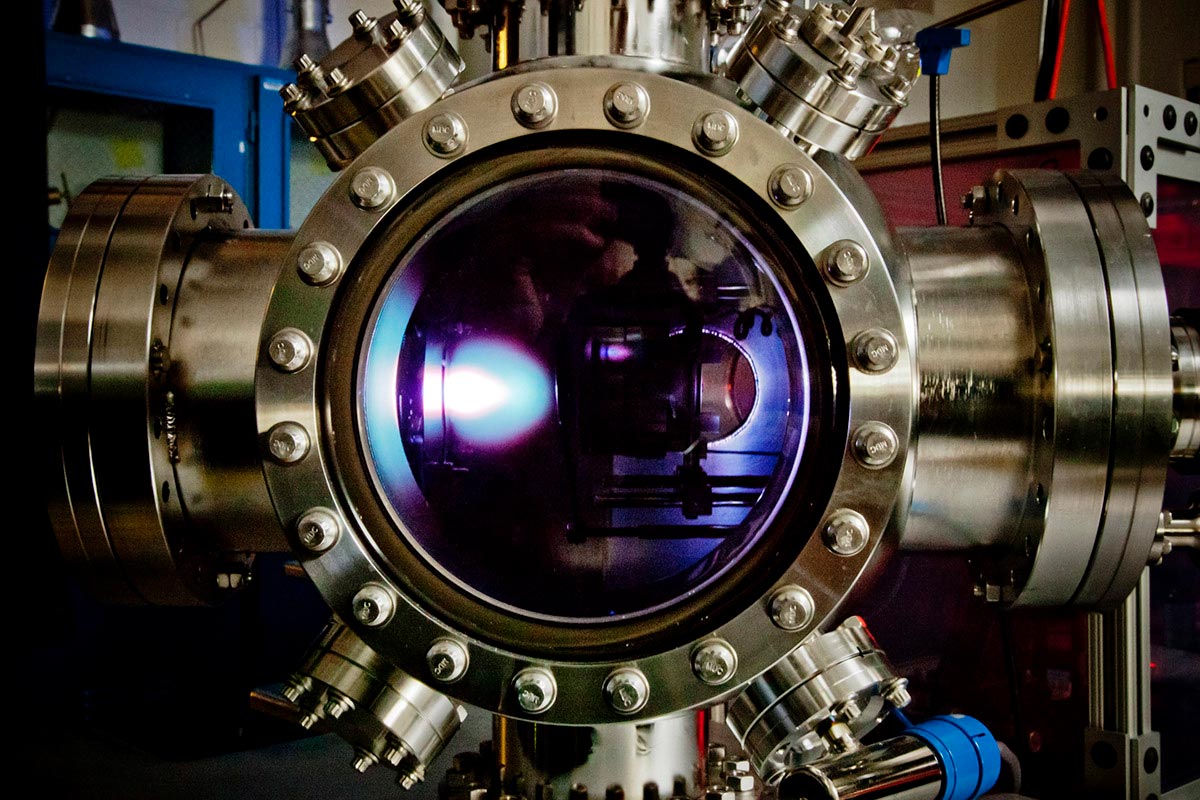

To create the new material, the thin film is first deposited via a pulsed laser deposition process in this chamber. The bright “plume” you see is the laser that strikes the target and sets the material down. Credit: Martin / UC Berkeley

By introducing defects to a common material, researchers at Berkeley Lab create a highly efficient capacitor with dramatically increased energy density.

Capacitors that store and release electrical energy rapidly are important components in modern electronics and power systems. However, the most commonly used have low energy densities compared to other storage systems such as batteries or fuel cells, which in turn can not quickly discharge and sustain charging without damage.

Now, as reported in the magazine Science, researchers have found the best of both worlds. By introducing insulating defects to a type of commercially available thin film in a straightforward step after processing, a team led by researchers at the Department of Energy’s (DOE) Lawrence Berkeley National Laboratory (Berkeley Lab) has determined that a common material can be processed into a top-performance energy storage equipment.

The research is supported by the Materials Project, an open access online database that provides the largest collection of material properties virtually to scientists around the world. Today, the Materials Project combines both computer and experimental efforts to accelerate, among other goals, the design of new functional materials. This includes understanding of ways to manipulate known materials in ways that improve their performance.

Growing demands for cost reduction and miniaturization of devices have driven a drive towards development of high energy density capacitors. Capacitors are often used in electronic devices to maintain power supply when a battery is being charged. The new material developed at Berkeley Lab was finally able to combine the efficiency, reliability and robustness of capacitors with the energy storage capabilities of larger-scale batteries. Applications include personal electronic devices, wearable technology, and audio systems.

The material is based on a so-called ‘relaxor ferroelectric’, which is a ceramic material that undergoes a rapid mechanical or electronic reaction on an external electric field and is often used as a capacitor in applications such as ultrasonics, pressure sensors, and voltage generators.

The applied field drives changes in the orientation of the electrons in the material. At the same time, the field drives a change in the energy stored in the materials, making them a better candidate for use than a small-scale capacitor. To solve the problem is how to optimize the ferroelectricity so that it can be charged at high voltages and be fairly discharged – billions of times or more – without maintaining damage that makes it unsuitable for long-term use in applications such as computers and cars.

Researchers in the lab of Lane Martin, a faculty scientist in the Materials Sciences Division (MSD) at Berkeley Lab and professor of materials science and engineering at UC Berkeley, achieved this by introducing local defects that allowed it to withstand larger voltages.

“You’ve probably experienced relaxing electricity on a gas grill. The button that illuminates the grill operates a spring-loaded hammer that strikes a piezoelectric crystal, which is a kind of relaxer, and creates a voltage that ignites the gas, “Martin explained.” We have shown that they can also be made into some of the best materials for energy-saving applications. “

Placing a ferroelectric material between two electrodes and enlarging the electric field causes charge buildup. During discharge, the amount of energy available depends on how strongly the electrons of the material are oriented, or become polarized, in response to the electric field. However, most such materials cannot normally withstand a large electric field before the material fails. The fundamental challenge is therefore to find a way to increase the maximum possible electric field without sacrificing the polarization.

The researchers turned to an approach they had previously developed to ‘expose’ conductivity in a material. By bombarding a thin film with high-energy charged particles, known as ions, they were able to introduce isolated defects. The defects capture the electrons of the material, preventing their movement and reducing the conductivity of the film due to orders of magnitude.

‘A ferro-electricity, which is meant to be insulators, is an important matter charge that leaks through them. By bombarding ferroelectricity with high-energy end trees, we knew we could make them better insulators, ‘said Jieun Kim, a doctoral researcher in Martin’s group and lead author on the paper. “We asked then, could we use the same approach to make a ferroelectronics against larger voltages and electric fields before it catastrophically fails?”

The answer turned out to be “yes.” Kim first manufactured thin films from a prototypical relaxer ferroelectric called lead magnesium niobite – lead titanate. He then set up the films with high-energy helium ions at the Ion-Beam Analysis Facility, operated by the Accelerator Technology and Applied Physics (ATAP) Division at Berkeley Lab. The helium ions struck target ions from their sides to create point defects. Dimensions showed that the ion-bombed film had more than twice the energy storage density of previously reported values and 50% higher efficiency.

“We originally expected the effects to be largely due to the reduction of leakage with isolated point defects. However, we knew that the shift in the polarization-electric field relationship was equally important because of some of those defects, ”said Martin. “This shift means that it takes larger and larger applied voltages to make the maximum change in polarization.” The result suggests that ion bombardment may help to overcome the trade-off between highly polarizable and easily fragile.

The same ion beam approach could also improve other dielectric materials to improve energy storage, and provide researchers with a tool to repair problems in already synthesized materials. “It would be great to see people using this ion-beam approach to ‘cure’ materials in devices after the fact if their synthesis or production process did not go perfectly,” Kim said.

Reference: “Ultrahigh capacitive energy density in ion-bombarded relaxor ferroelectric films” by Jieun Kim, Sahar Saremi, Megha Acharya, Gabriel Velarde, Eric Parsonnet, Patrick Donahue, Alexander Qualls, David Garcia and Lane W. Martin, July 3, 2020, Science.

DOI: 10.1126 / science.abb0631

This research was supported by the DOE Office of Science and grants from the National Science Foundation.