U.S. Army researchers have partnered with Texas A&M University to create a new polymeric material that can shift and heal autonomously as part of a research effort to improve future unmanned aerial vehicles and robotic vehicles.

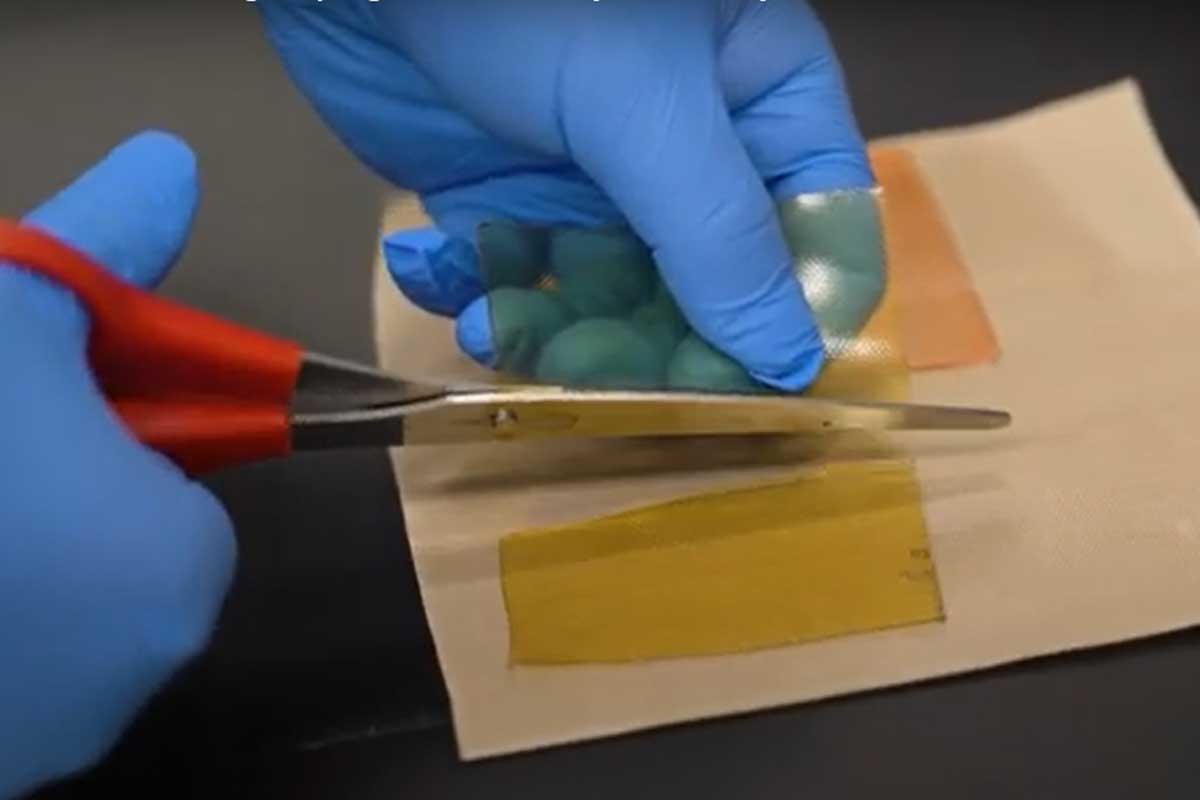

In early research, the first-of-its-kind, 3D-printable epoxy-based material may respond to stimuli, and researchers hope it will one day have integrated intelligence that allows it to adapt to its environment without external control, according to a news release from Army Combat Capabilities Development Command’s (CCDC) Army Research Laboratory.

Read the following: Mortar Shells Strike Kabul as Afghans Mark Independence Day

“We want a system of materials to provide structure, sensing and response at the same time,” said Frank Gardea, an aerospace engineer and lead researcher for the effort, at the CCDC.

Gardea sees a future platform, suitable for air and ground missions, with the “reconfiguration characteristics of the T-1000 character in the Hollywood movie, ‘Terminator 2.'”

The hit film included a Terminator made of liquid metal that could shape his arms into stacking weapons and heal himself after he was shot with everything from a 12-gauge rifle to a 40mm grenade launcher.

To date, the material has responded to temperature, which researchers first selected because of its ease of use during laboratory tests.

In the real world, applying a temperature stimulus is not as easy as it is practical, so they introduced light responsiveness because it is easier to remotely control and apply, Gardea said in the release.

Polymers are made of repeating units, such as links on a chain. For softer polymers, these chains are only lightly connected to each other via crosslinks, according to the release. The more crosslinks between chains, the more rigid the material becomes.

“Most crosslinked materials, especially those that are 3D-printed, have a tendency to solidify, which means that once you produce your part, the material cannot be processed or melted,” Gardea said, adding that this new material provides a “dynamic bond that allows it to flow multiple times from liquid to well, allowing it to be 3D printed and recycled.”

These dynamic bands result in a unique behavior of shape memory, so the material can be programmed and triggered to return to a memory shape, according to the release.

“The flexibility introduced to the polymer chain allows it to be fine-tuned in unusual ways, both to obtain the softness of rubber or the strength of the plastic carrier,” the release adds.

Much of the previous work on adaptive materials was for materials systems that are too soft for structural applications or otherwise unsuitable for platform development, said Bryan Glaz, associate chief scientist for the lab’s Vehicle Technology Directorate, in the release.

The investigation is still in the discovery phase. The team began trying to develop a 3D printable material for structural applications that could be used to print components of UAVs or even rotorcraft, according to the release.

During this exploratory study, program officials noted that, after the failure, the surfaces became active and “would easily stick together,” Gardea said, adding that the discovery prompted researchers to investigate the possibilities for self-healing.

The immediate next steps are improving acting behavior and healing, as well as introducing more responsiveness, and have the material respond to stimuli above temperature and light, Gardea said.

This effort is simply part of an exploratory research program to look at new scientific developments that could disrupt current scientific and technological paradigms 30 to 50 years from now, Glaz said.

But the team’s scientific advancement marks “a first step along a very long path towards realizing the scientific potential for deep future platforms,” he added.

– Matthew Cox can be reached at [email protected].

Related: Marines fly large, new surveillance drones in Australia as they test unmanned call missions

Show full article

© Copyright 2020 Military.com. All rights reserved. This material may not be published, broadcast, rewritten or redistributed.